Remove Metal Contaminants from Powder and Bulk Applications

Bunting® manufactures products that serve global markets and include a broad range of Magnetic Materials. The Powder and Bulk Industry specifically uses Magnetic Separation Systems and Metal Detection Equipment to detect and remove metals from chemical or powder applications. Below you will see how we use different products in order to make your plant safer and more efficient.

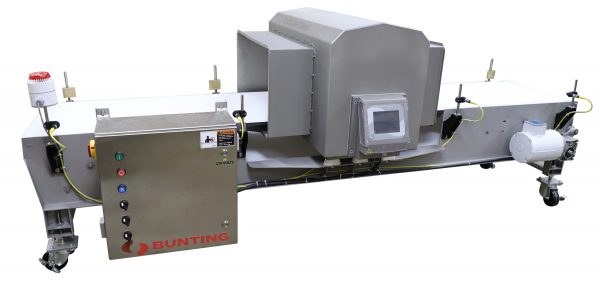

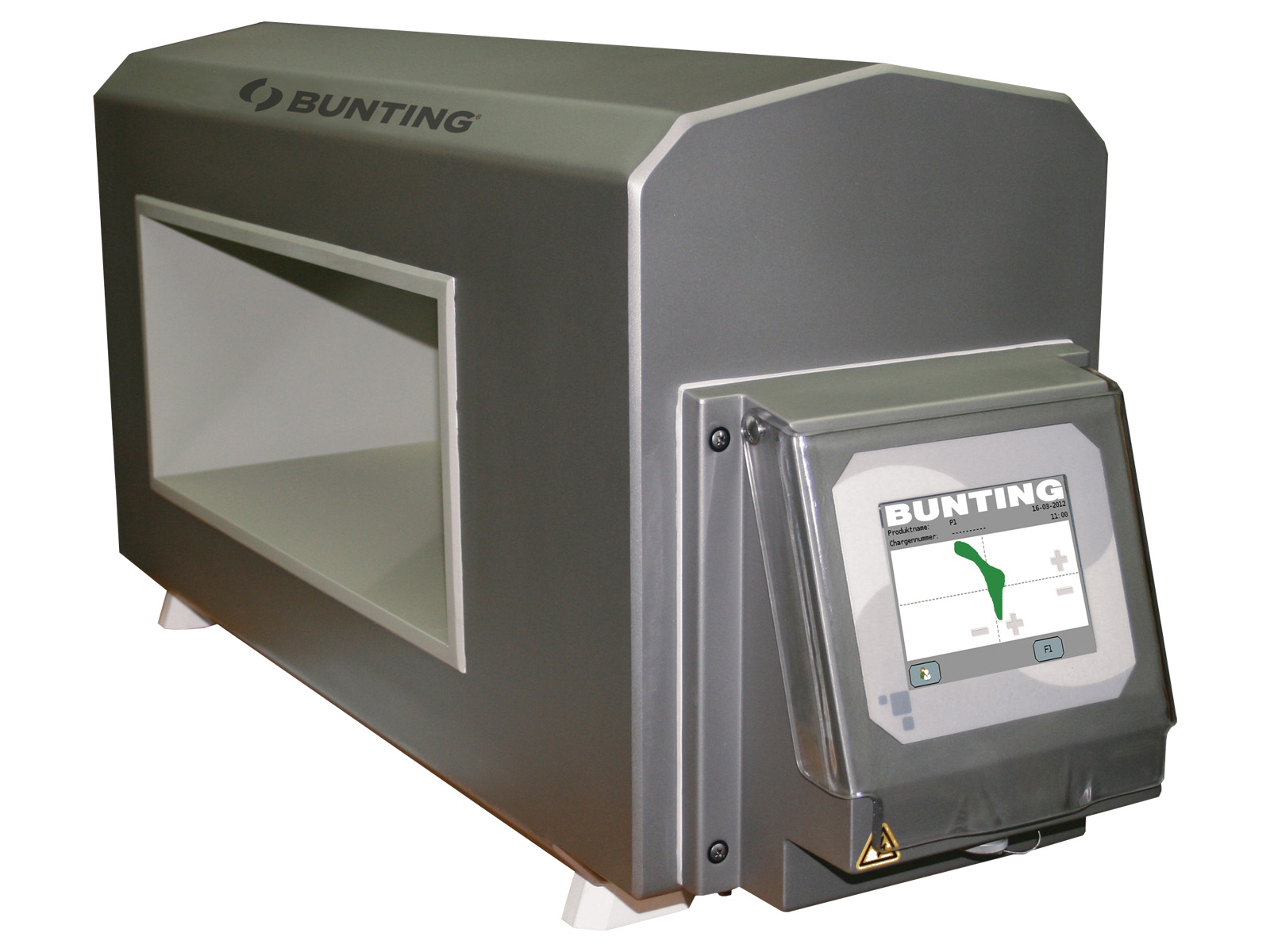

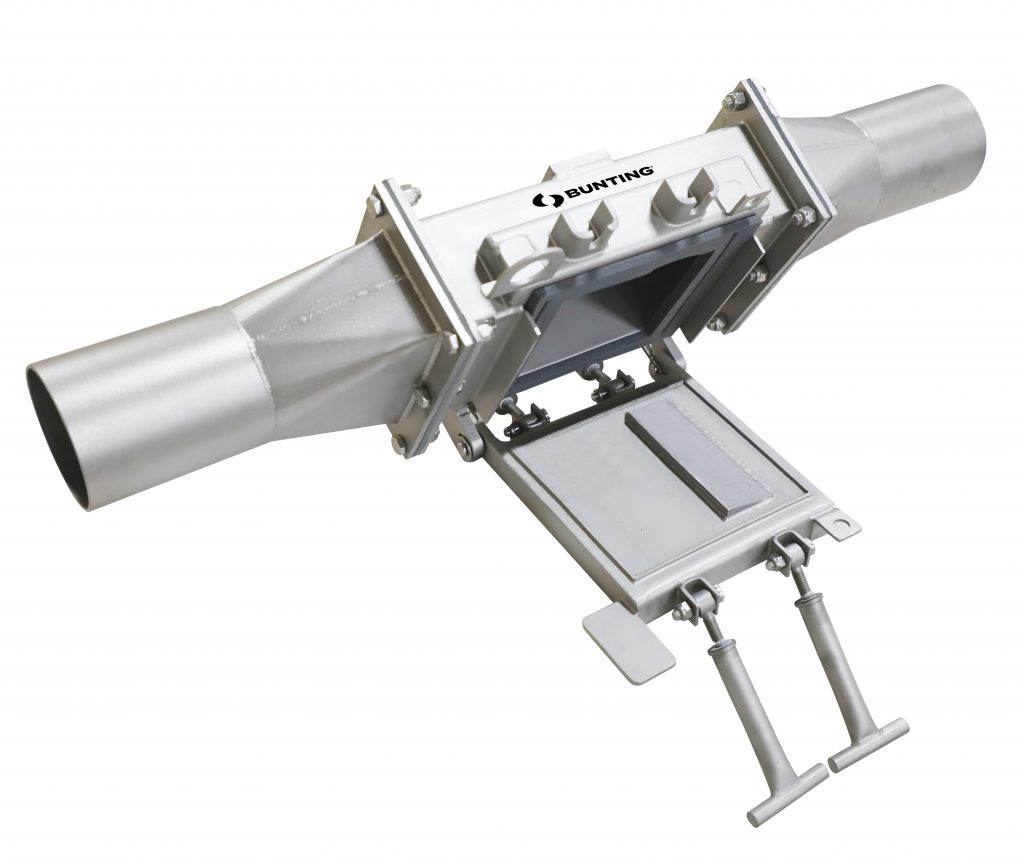

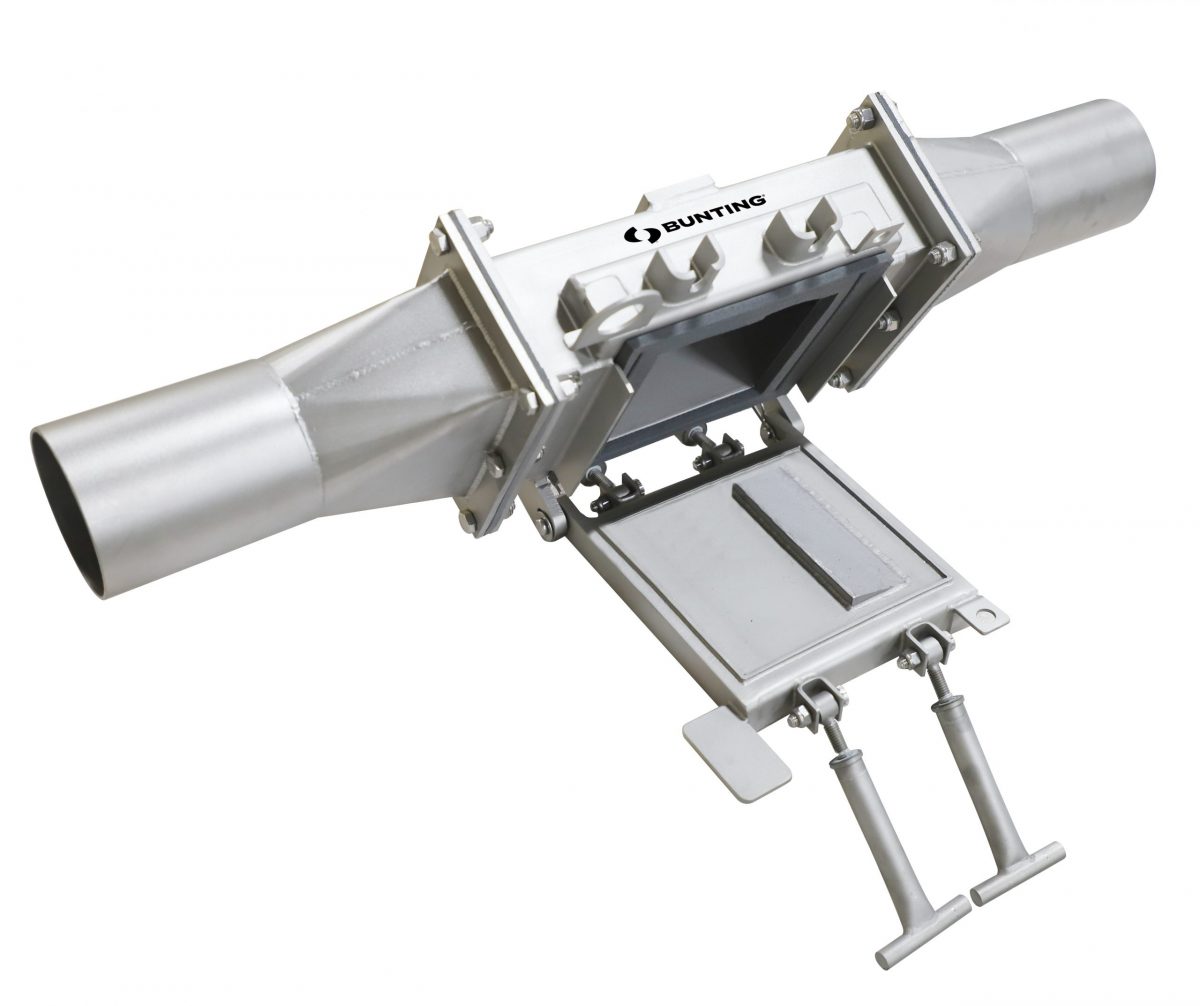

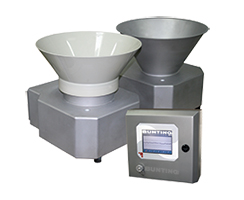

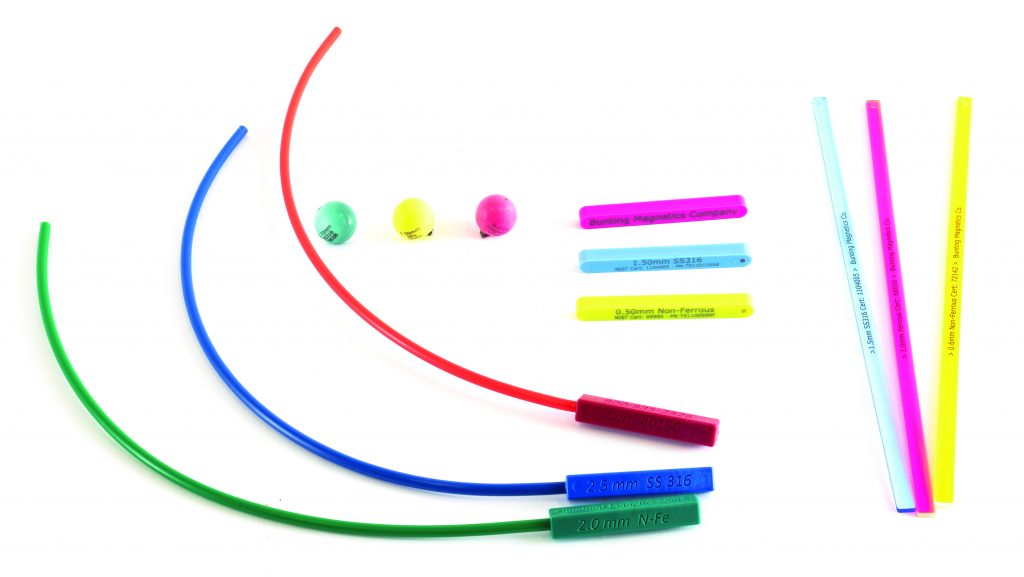

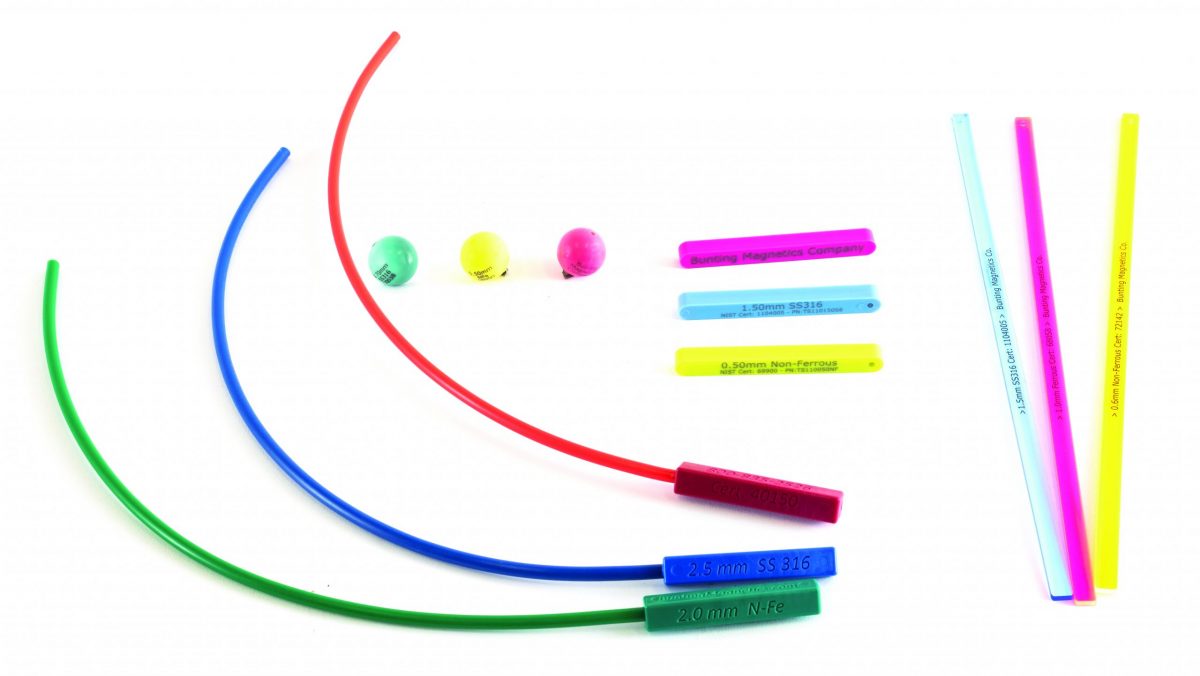

Metal Detection

Successful detection and separation of metal will protect your processing equipment from damage, which saves your organization money and downtime. The most common type of foreign material within processing is metal. Let our Metal Detectors sense and remove the presence of ferrous, non-ferrous and stainless metals in the process flow. All food-grade (or higher) come standard with Metal-Detectable Gaskets & Grommets for an added layer of product safety and brand protection.

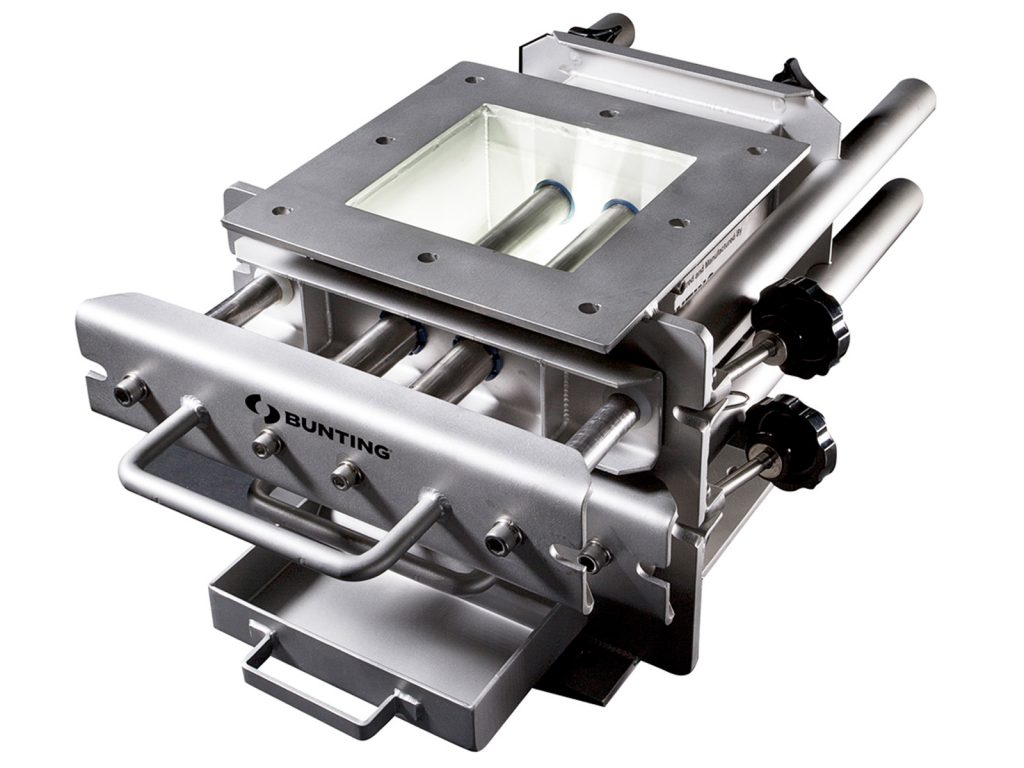

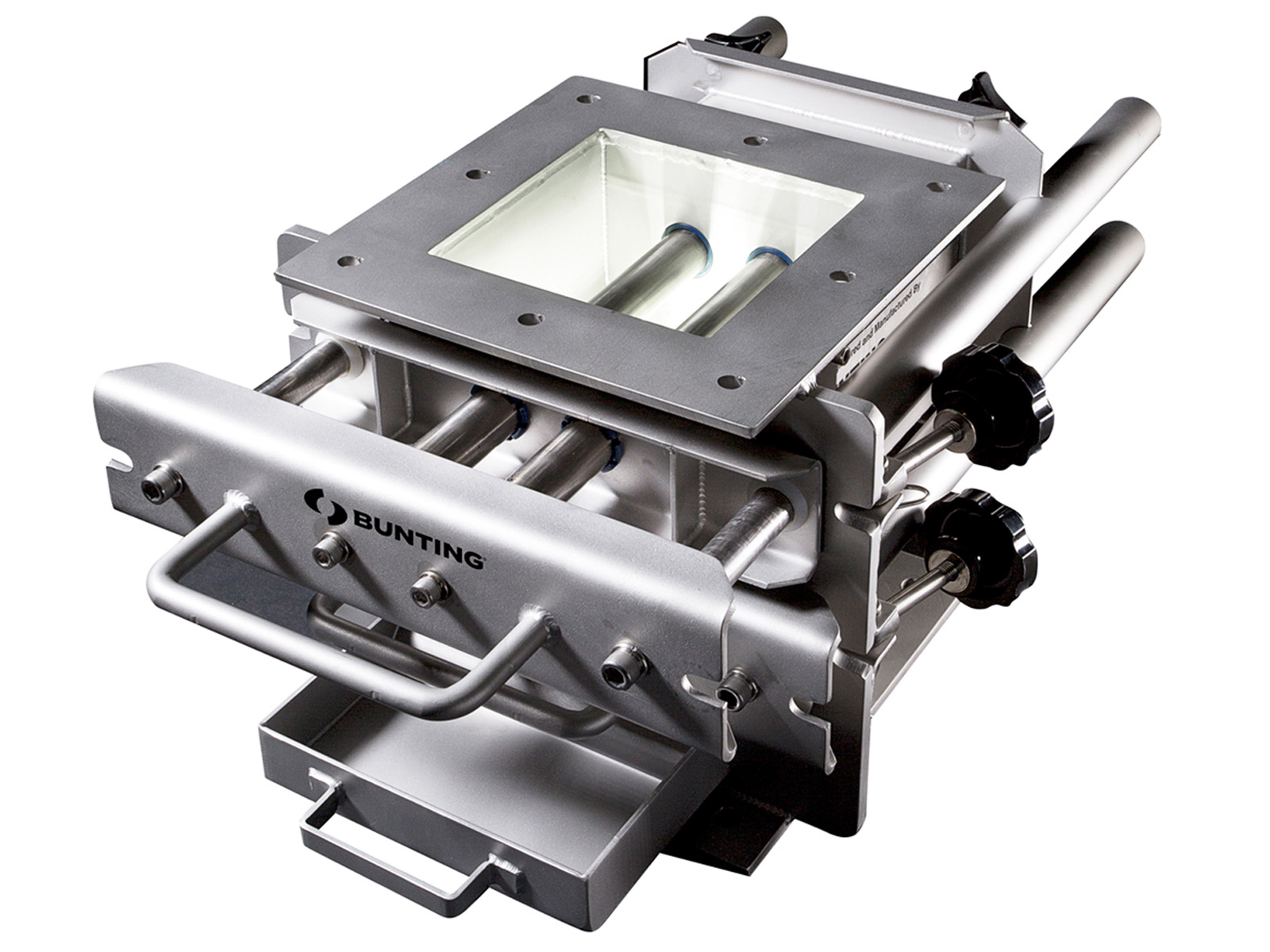

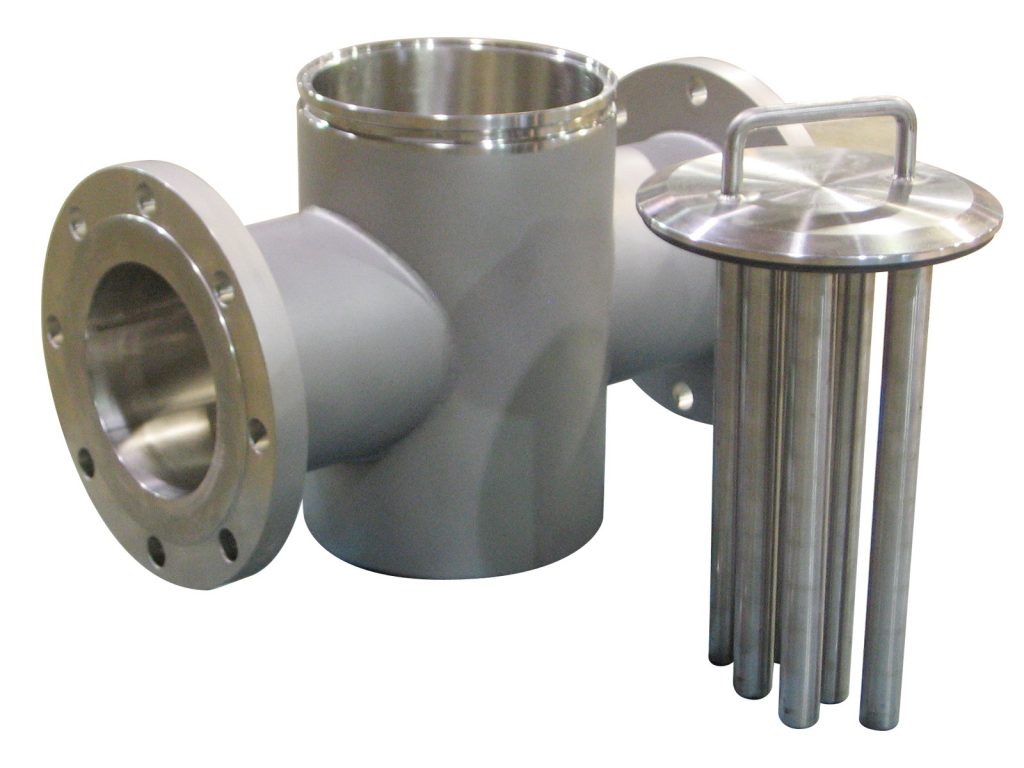

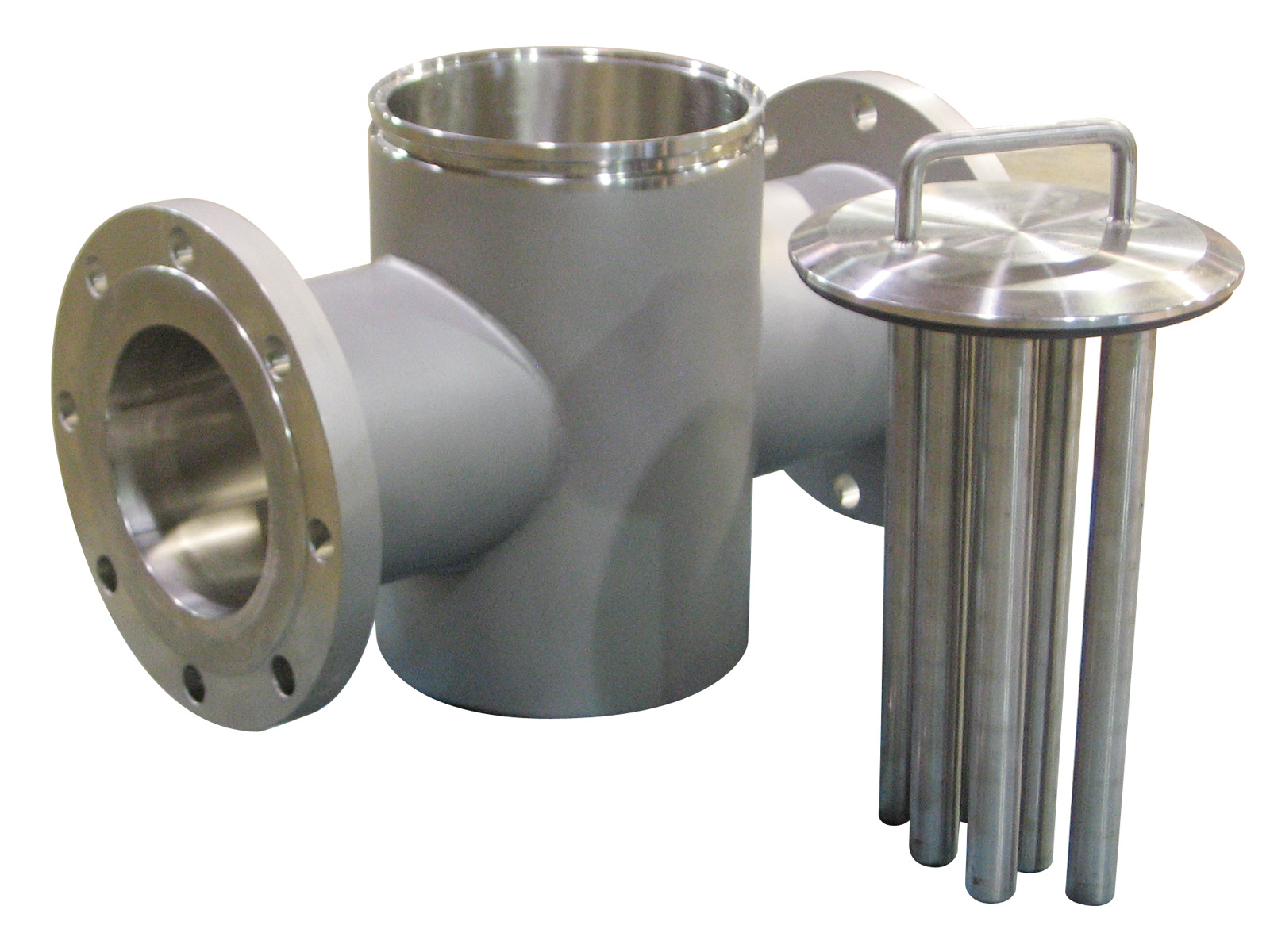

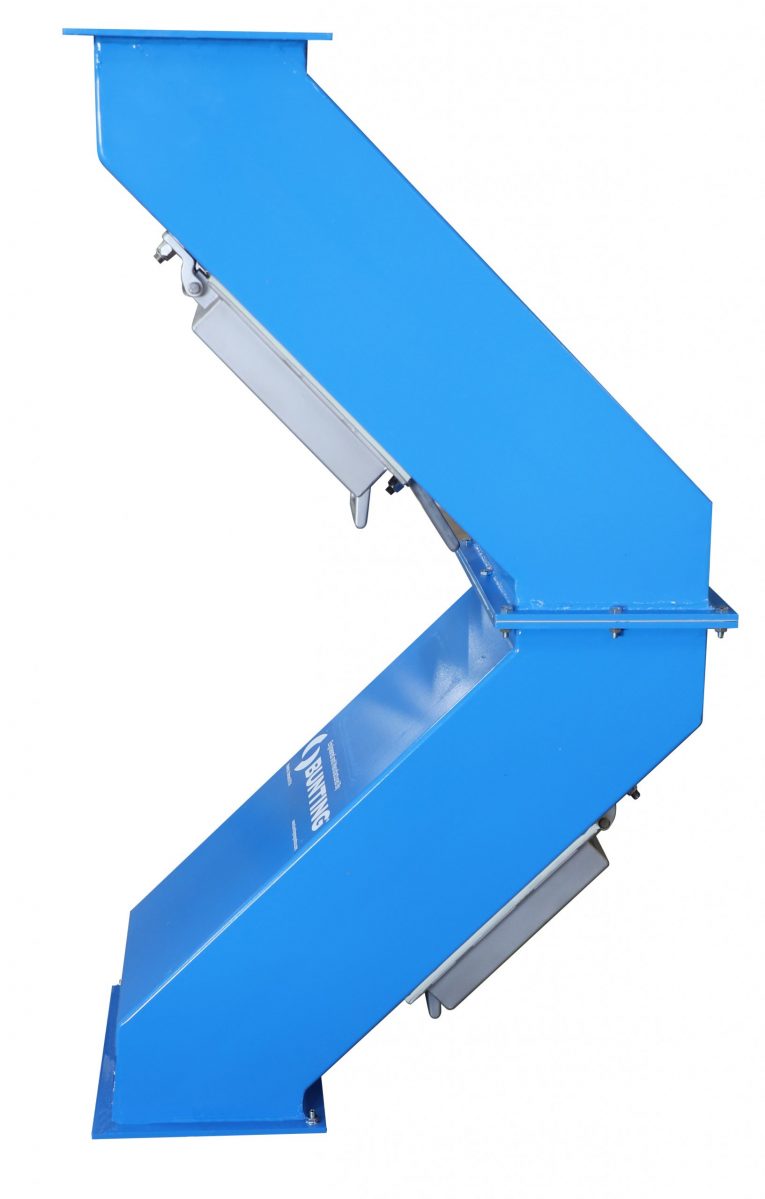

Magnetic Separation

Our lineup of magnetic separation equipment is designed to remove metal contamination from gravity, mechanical, or pneumatic conveying systems. The wide range of models that we manufacture can handle virtually any application with thorough removal of metal tramp. They can be ordered to meet specific construction standards and customized to satisfy special requirements.

Click here to view our Powder and Bulk catalog.