Remove Metals During Grain and Milling Processing

Bunting® manufactures Metal Detection Equipment, Magnetic Separation Systems, and Material Handling Conveyors for the Grain and Milling Industry.

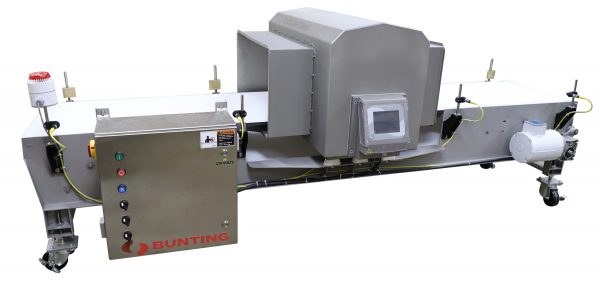

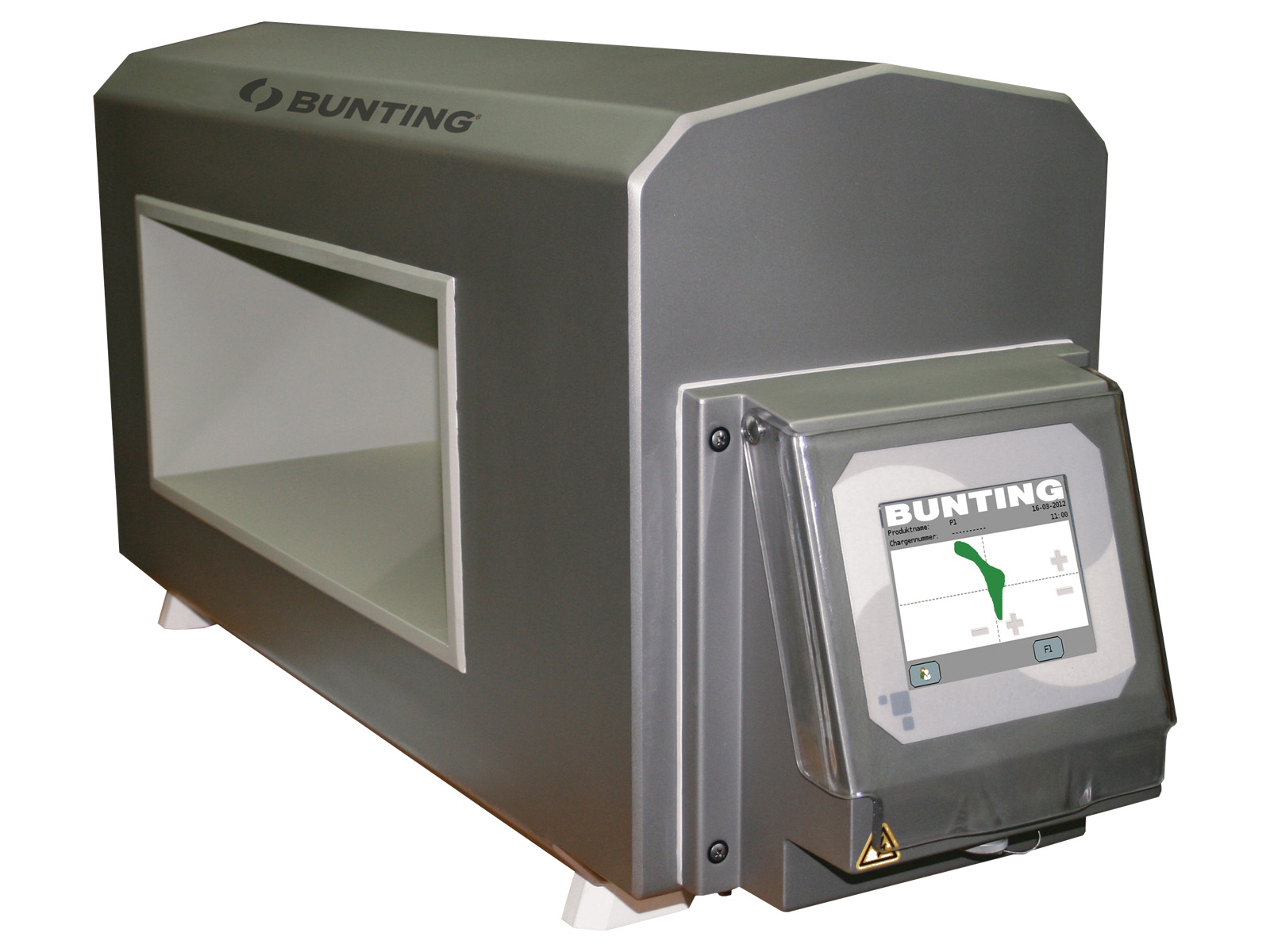

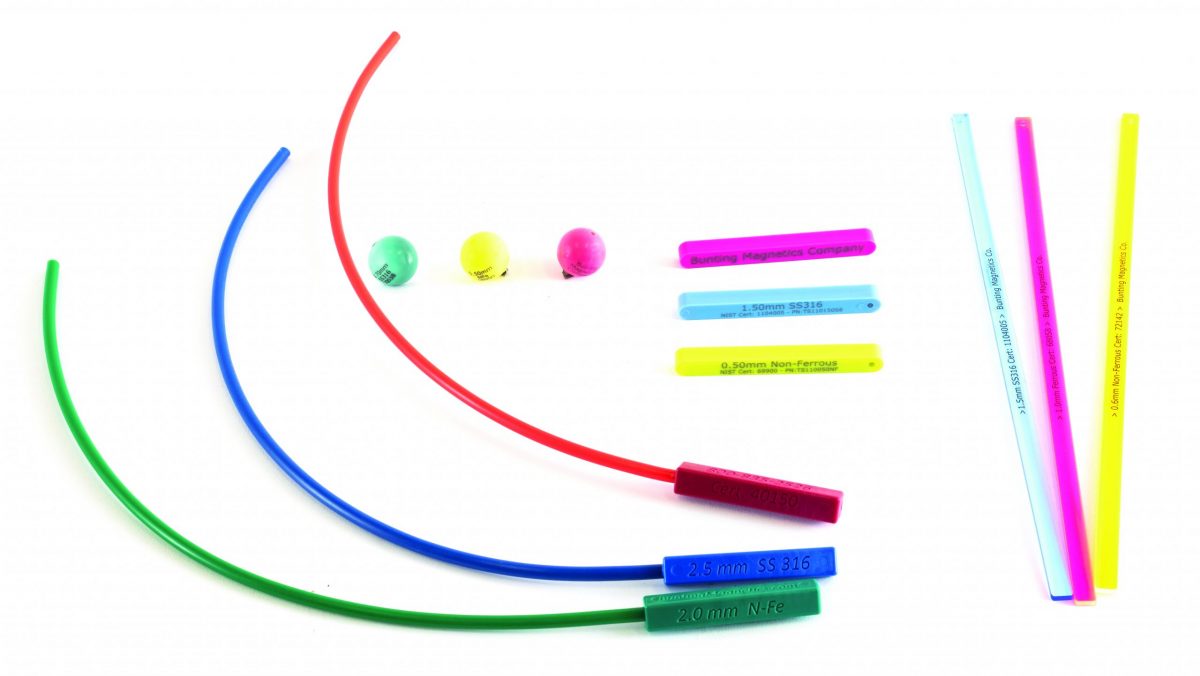

Metal Detection

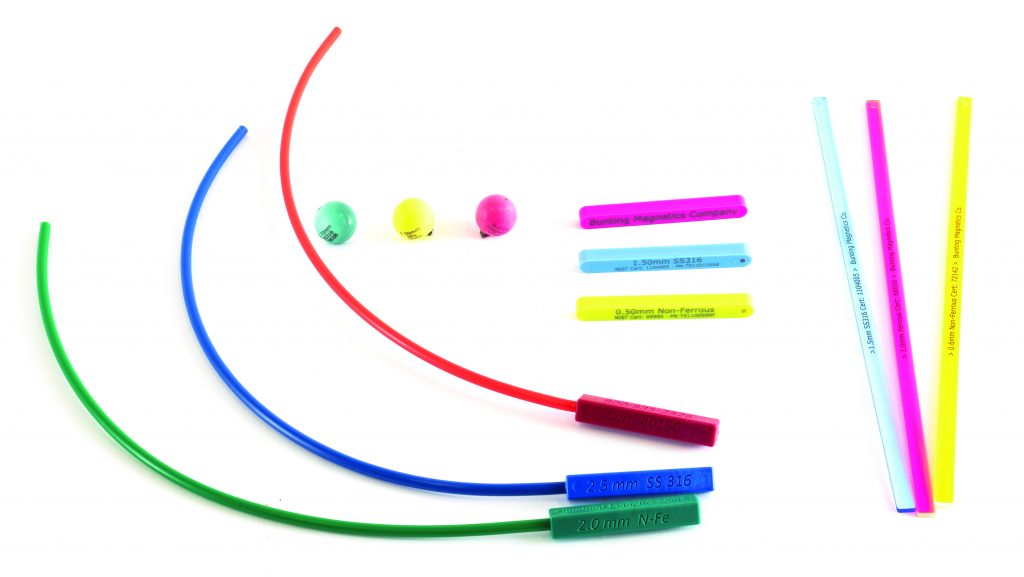

The most common of foreign material within grain and milling processing is metal. Successful detection and separation of metal will protect your processing equipment from damage, and prevents safety hazards for consumers. Bunting® Metal Detectors cover a full range of industrial applications, whether processing or packaging. All food-grade (or higher) come standard with Metal-Detectable Gaskets & Grommets for an added layer of product safety and brand protection.

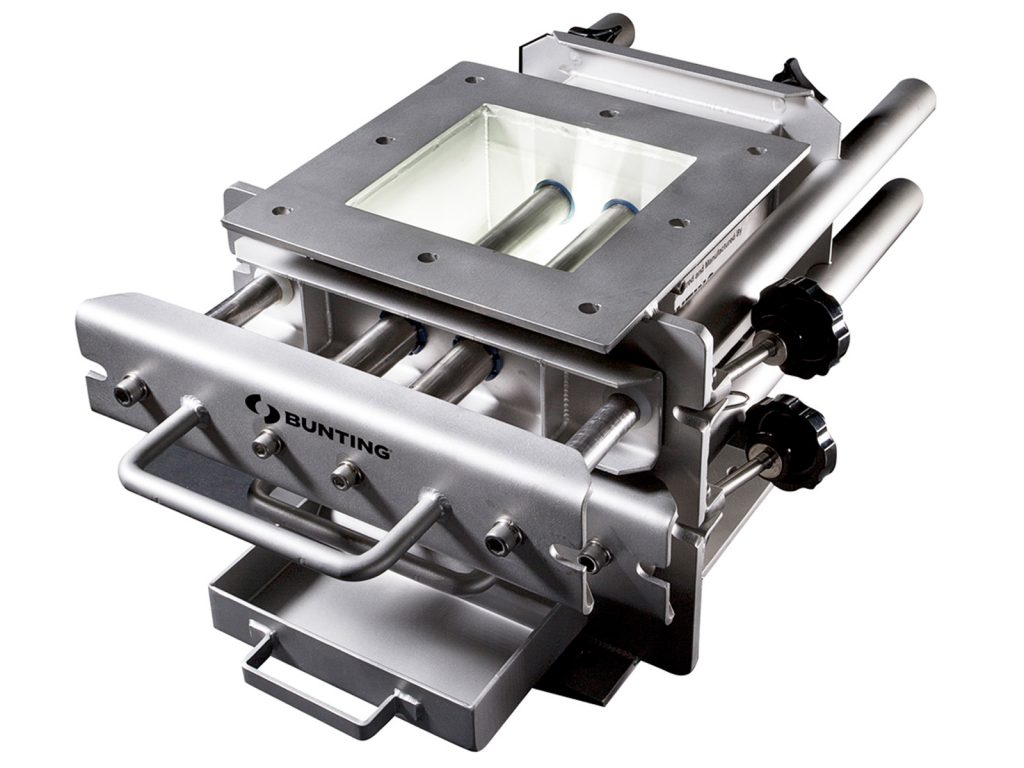

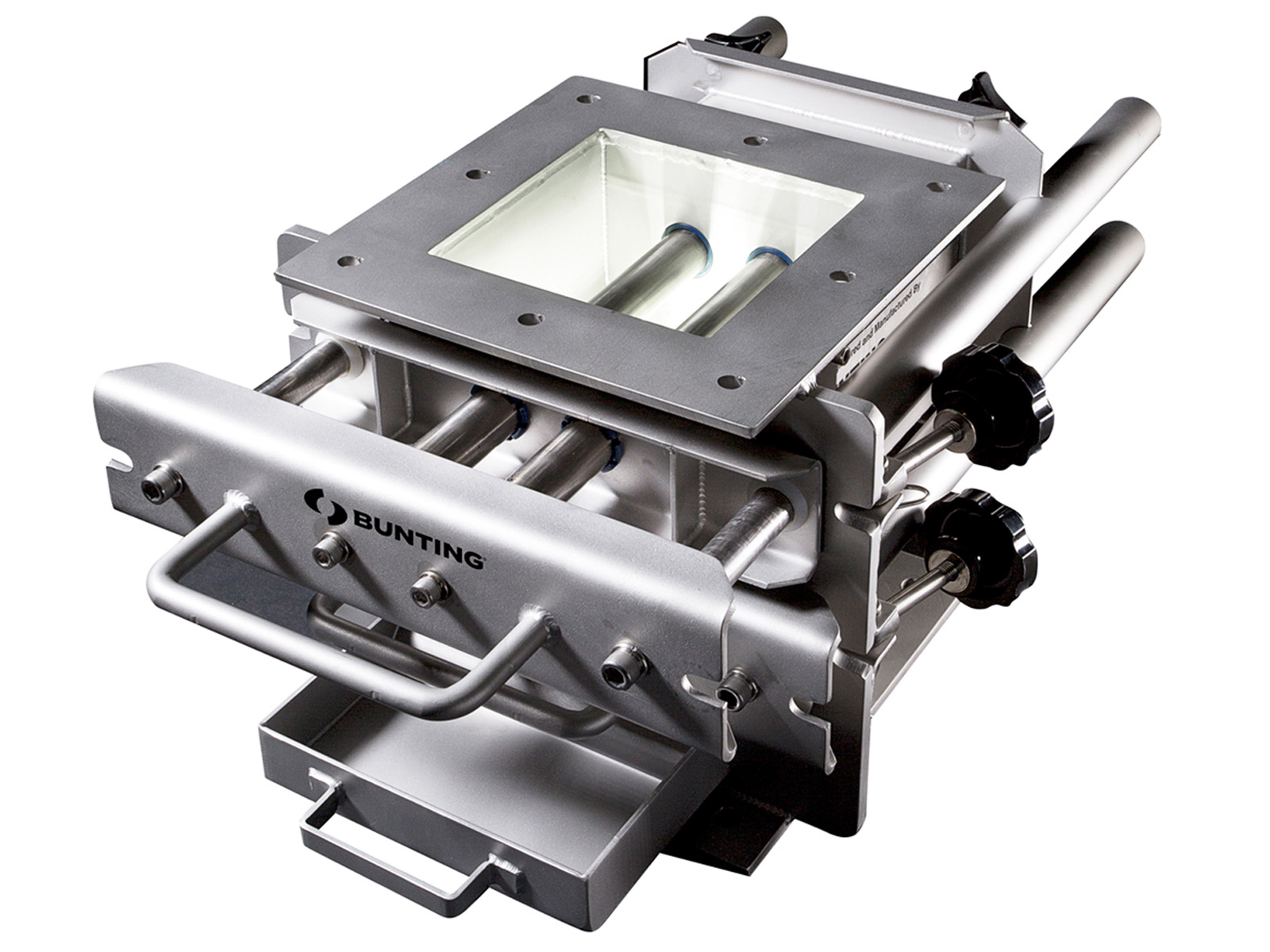

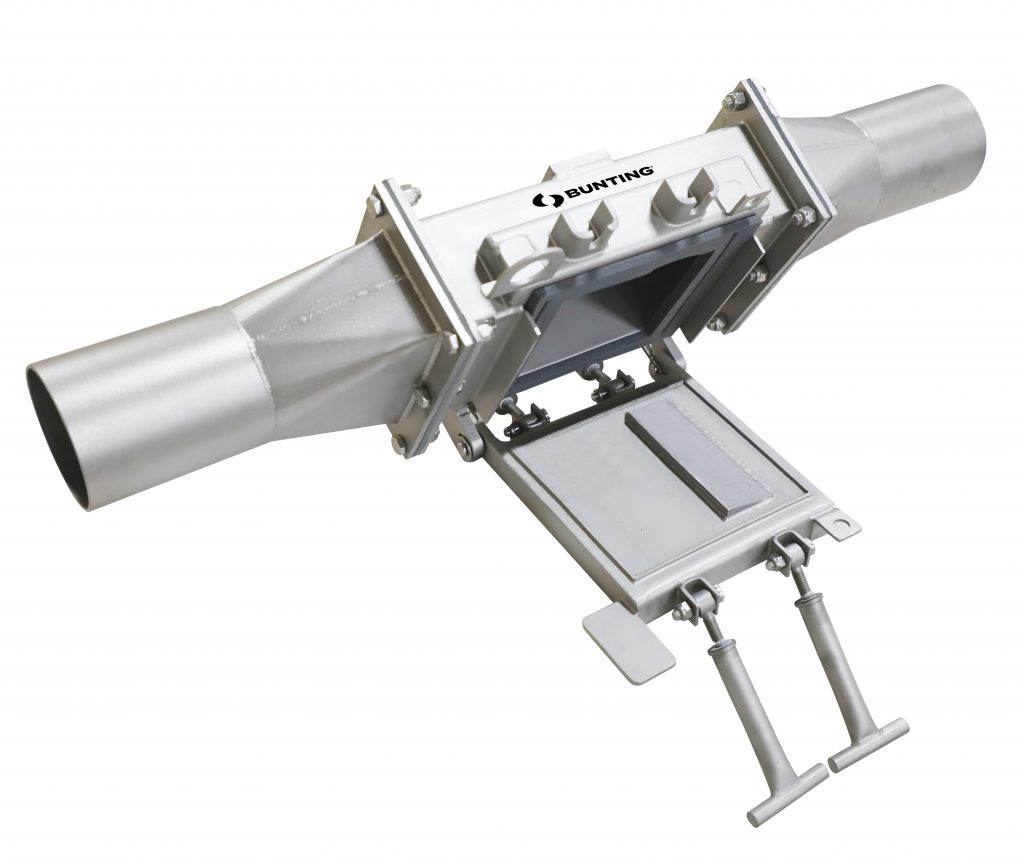

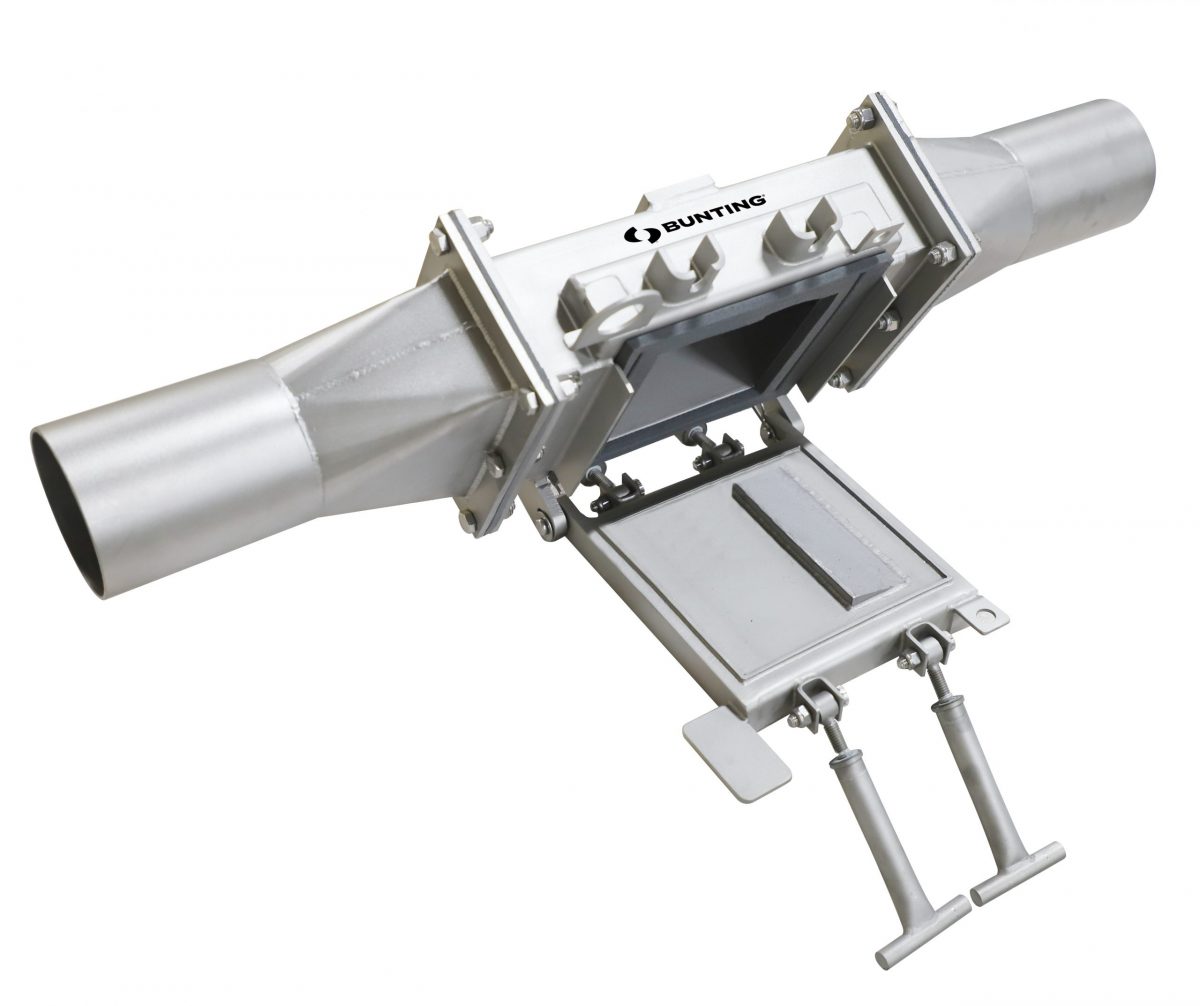

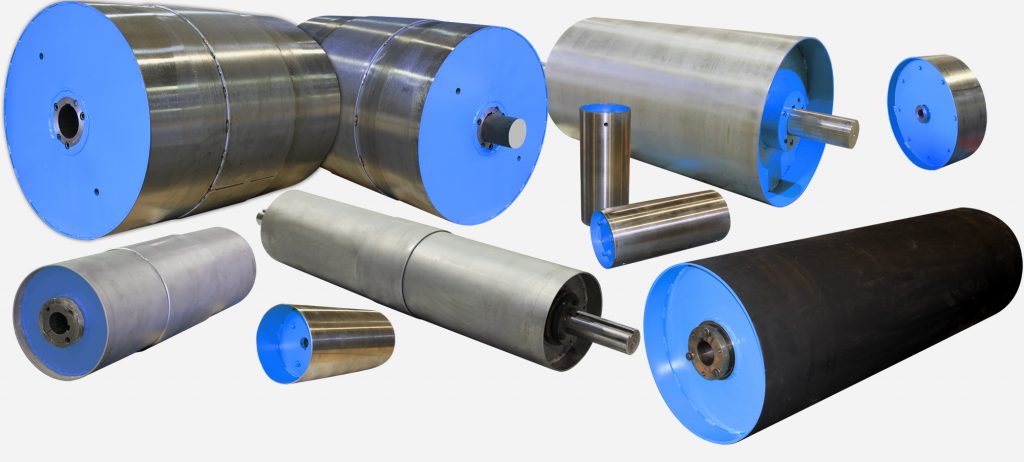

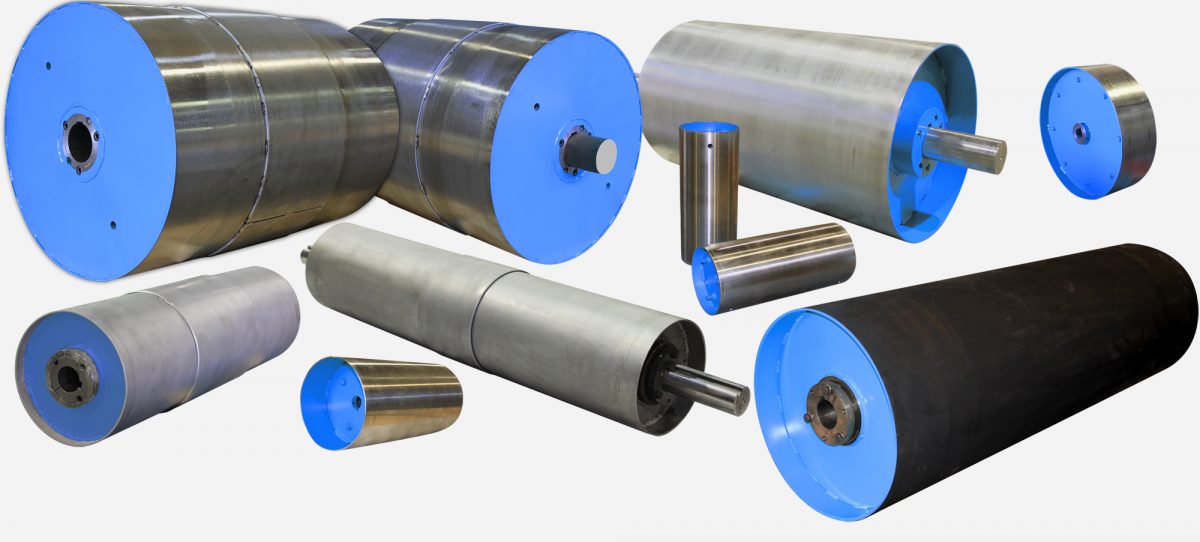

Magnetic Separation

Our Magnetic Separators come in a wide range of models to handle virtually any applications with exceptionally thorough removal of metal tramp. You can rely on our equipment and expertise to eliminate product contamination and damage to machinery from tramp metal.

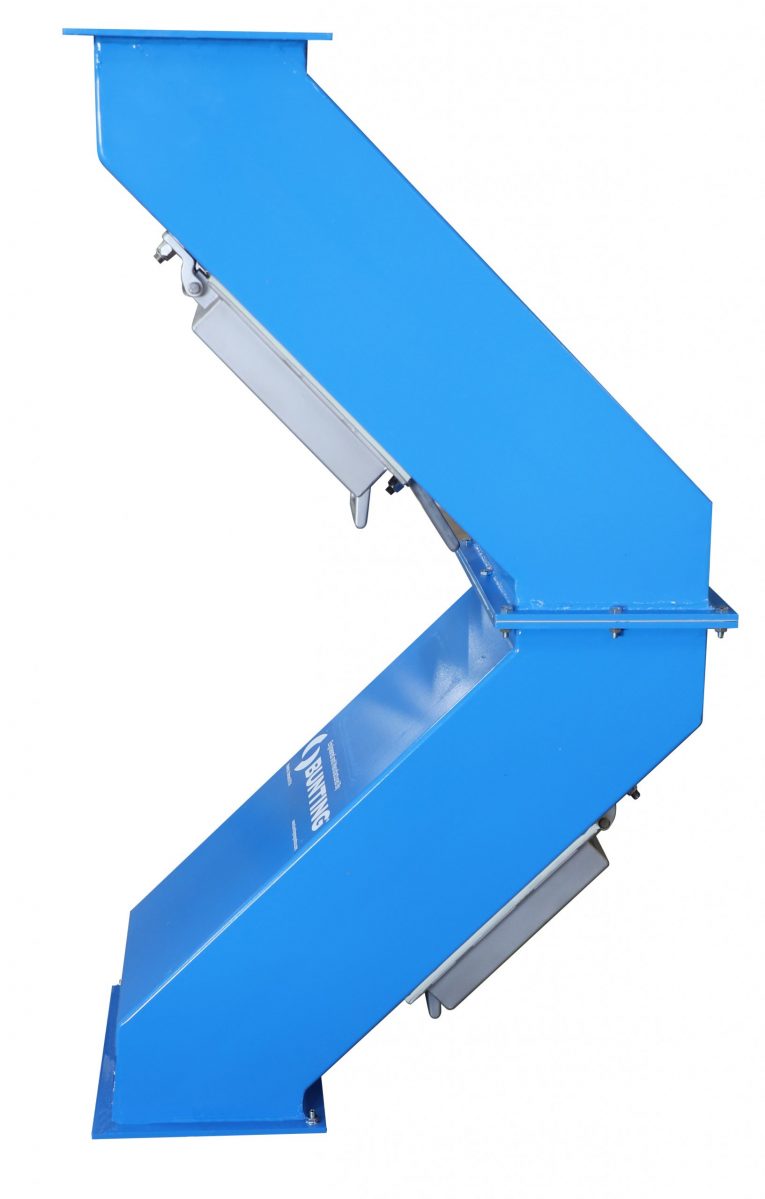

Material Handling Conveyors

Whether you are planning a plant-wide update or streamlining a specific operation, we can supply standard solutions or design and build custom packages to meet your objectives. Our Material Handling Conveyors can move your materials quickly and efficiently where you need them.

Perfect Grain & Milling Plant

Successful detection and separation of metal will protect your processing equipment from damage, which saves your organization money and downtime. Click here for a Perfect Grain & Milling Plant diagram.