In our pipeline style metal separators series, we have two styles, the pipeLINE™ system is used for liquids or pastes in pressure conveying lines. The meatLINE™ system is also used for ground meat but it uses simple integration with a vacuum filter.

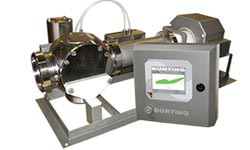

pipeLINE™

Designed to remove ferrous and non-ferrous metals from liquids, pastes, or slurries. Various sizes available, and works well with many different types of products.

- Custom designed systems fit any pipeline application requirements. Built to your specifications and comes ready for installation.

- The 3-way separation mechanism is suitable for both pneumatically-driven pig cleaning and Clean in Place (CIP).

- Features 05 or 07 controls, the most advanced metal detection controls, delivering superior results with ease of use.

meatLINE™

The meatLINE allows to detect and separate ferrous and non-ferrous metals from ground meat products as they are pumped toward stuffers or patty formers. The uniquely designed reject mechanism will remove metal contaminants without damaging the integrity of the ground meat.

- Detects and separates any type of metal, encapsulated or free

- Fits all commercial vacuum fillers

- Reject mechanism can be easily disassembled and cleaned without the need for tools

- All reject components are secured with a loss prevention device

- Pressure washer safe

- Easy and fast operation through Touch Screen Display with self-explanatory menu structure

- All components are made of stainless steel or food-safe plastic. It features a responsive, powerful and permanently maintenance-free pneumatic drive for a long lifespan.