Benefits

While primarily used in auto recycling applications, the CBS MAX is also a great fit for municipal recycling (MRF) and construction and demolition (C&D) recycling applications. Wherever you are working with tough, dirty, and difficult material, you can count on the CBS MAX to get the job done.

- Powerful permanent magnets deliver the highest level of separation, removing ferrous contaminants and leaving you with a high-purity end product.

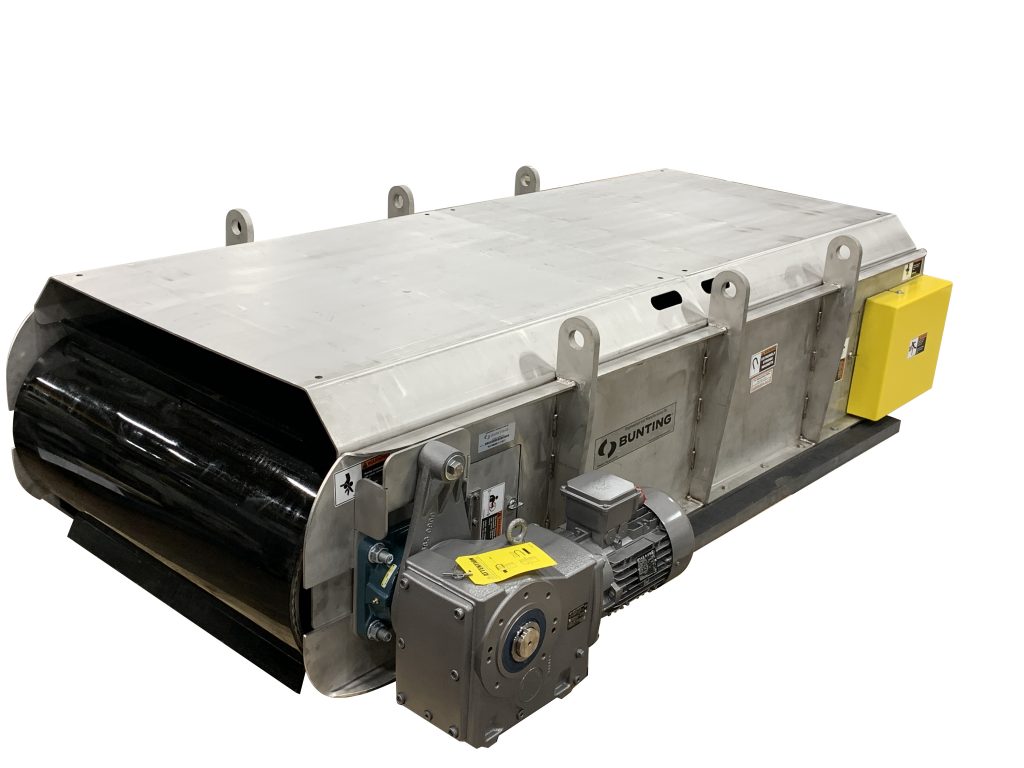

- Complete stainless steel frames designed not to collect ferrous scrap on their sides.

- Offers one of the toughest cut-resistant belts in the recycling industry.

- Continuous removal of ferrous contaminants maximizes product purity.

- Fully customizable to suit your exact needs and integrate perfectly with your existing equipment.

Specs

- Built in with 4 magnetic widths for extended reach-out requirements.

- Oversized 16” diameter “Mine Duty” heavy duty stainless steel pulleys won’t get magnetized.

- Oversized shafts utilize standard off the shelf heavy duty oversized dodge bearings.

- PVC 200 combined with a ¼ top cover of tough, cut-resistant urethane and urethane cleats efficiently pull off separated ferrous metal while minimizing likelihood of cut damage.

- 3hp Nord Gearmotor for commonality for stocking spare parts, set to run at approximately 300fpm to discharge ferrous metals.

- Top debris covers provided to protect belt from the elements and protect unit from potential damage caused by overhead debris falling onto it, as well as protecting the belts from the weather.

- Manganese baseplate for high wear and impact resistance.

- Side access door ports enable convenient maintenance and tramp removal if needed.