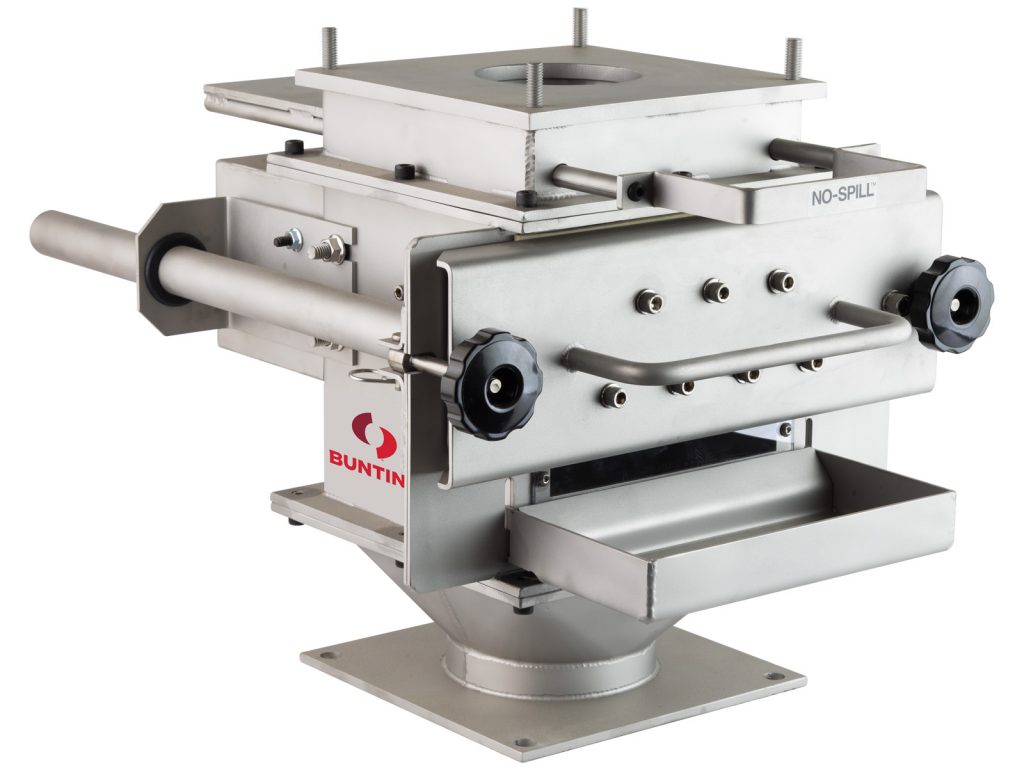

Gravity Metal Separators – Recycling and Plastics

Bunting has a full line of gravity style metal detectors that we have designed specifically for the needs of customers working in the recycling and plastics industries. Our gravity feed metal detectors automatically detect all ferrous metals, non-ferrous metals, and stainless steel. Once metal contamination has been detected, Bunting’s gravity metal detectors swiftly reject the contaminated material and separate it out of your product stream. Our reject mechanisms are designed so that metal contamination will be thoroughly removed while minimizing loss of good product. Request Quote