Plate Rails for almost every kind of Conveyor

Bunting manufactures the strongest rails in the industry. Magnetic Plate Rails can be utilized on Flat Belted Conveyors, Mattop Conveyors, Table Topped Conveyors, Cable Conveyors and Sideflex Mattop and Table Topped Conveyors in both horizontal and inclined applications.

- Available in both the economical Ceramic and the high intensity Neo Rare Earth Magnets for maximum holding.

- Constructed in standard, food grade and sanitary grade construction.

- Flat plate rails, lugged plate rails, and curved plate rails are options.

Standard Rare Earth Flat Plate Rails

Come in three strengths for most mattop inclined wet or wash-down applications.

Standard Rare Earth Lugged Plate Rails

For most tabletop inclined wet or wash-down applications. The live pole lugs transfer the magnetic strength into holding the can tighter and straddle the chain lug.

Standard Ceramic Flat Plate Rails

Come in three strengths and are more economical rails for flat belt horizontal and lower inclined applications.

Standard Ceramic Lugged Plate Rails

More economical rails for table topped horizontal and lower inclined applications. The live pole lugs transfer the magnetic strength into holding the can tighter.

Curved Rare Earth and Ceramic Plate Rails

Designed for all types of conveyor belting material and for any angle and radius. These rails are designed in all the above styles to match the magnetic strength and application requirements.

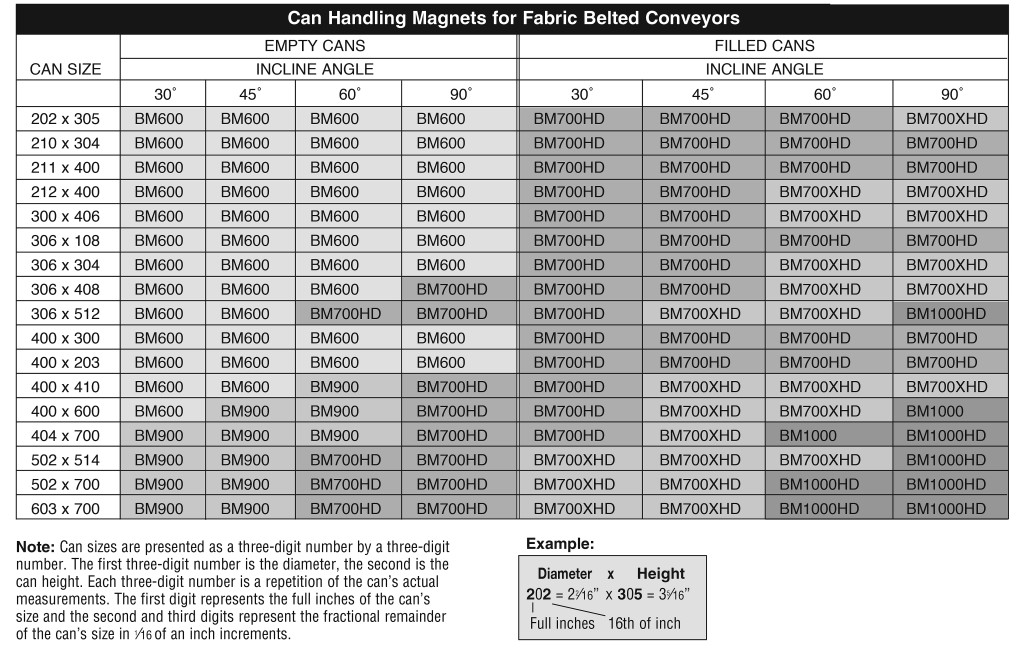

Magnetic Rail Specification:

The following chart is a selection guide for the proper Bunting Magnetics Co. magnetic rails needed for inclined magnetic fabric belted elevation conveyors for both empty and full cans. This chart is only relevant for textured (not slick) fabric belts under .120” thick and with can speeds under 120 feet per minute. Inclined nose-over magnetic conveyors over 120 fpm should have a corner magnetic pulley to reduce friction and belt loading. Also for belt speeds over 120 fpm and for all Mattop belting application, please consult Bunting Magnetics Co. for stronger magnetic rail recommendations.