Install torpedo magnets in Just-In-Time hopper loaders for up to 98% removal of tramp metal contamination.

Torpedo magnets from Bunting are designed to be used “Just-In-Time” (JIT) hopper loaders, and deliver a high standard of magnetic separation in a compact size and shape.

A torpedo magnet consists of a formed stainless steel ring, which is welded to a high-energy rare earth magnetic cartridge. The bottom of the torpedo magnet is a live magnetic pole that allows tramp metal to collect and hide, preventing tramp metal from wiping off and reentering the product stream.

A torpedo magnet is installed so that it hangs in the center of a Just-In-Time loader’s glass tube. This method of installation positions the torpedo magnet so that it can efficiently capture tramp metal before it reaches your plastic molding machine. The torpedo magnet can be inspected for tramp metal buildup simply by looking through the loader’s glass tube. Then, the magnet can be removed and cleaned as required. The material level sensor, which is typically mounted on the outside of the Just-In-Time loader’s glass tube, will not be affected by the torpedo magnet.

Torpedo magnets are available in either 1” or 5/8” diameter high-energy rare earth magnetic cartridge designs. The diameter of the ring (A) should be larger than the hopper opening. We stock four sizes to fit most Just-In-Time loaders. Choose our 5/8” diameter torpedo magnets for applications where the sight glass is 2 ¼” in diameter or less. For sight glasses larger than 2 ¼”, select 1” diameter torpedo magnets.

Torpedo magnet deliver high performance magnetic separation that is suitable for small spaces.

powerLINE™ 07

The powerLINE™ 07 is easily integrated into existing systems in your facility. It offers simplicity of operation combined with ultimate reliability when detecting metal in gravity free-fall applications, pressure or vacuum lines.

Special Features:

• Patented powerline™ coil technology incorporates an integrated sensing tube into the coil construction, allowing product to flow closer to the coil for greater sensitivity.

• Integral inlet and outlet stubs with Jacob connections shield coil from environmental interferences, delivering superior reliability and requiring less installation space.

• Can be installed either vertically or horizontally.

• Features advanced 07 controls, the most advanced metal-detection controls, delivering superior results and with greater ease of use. Also available with our 05 control package.

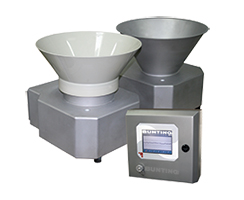

flatLINE™ 07

The flatLINE™ 07 is a low-profile metal detector designed for installation in gravity free-fall applications. It is ideal for multi-head weighers and vertical bag-filling machines where space is limited.

Special Features:

• Compact and versatile. Requires minimum installation heights, allowing it to easily fit in tight spaces.

• Comes equipped with our AMD 07 digital controls with touch pad. Also available with 05 control package.

• Powerline coil construction delivers the smallest metal-free zone possible, while shielding the search head from outside interference.

• Flexible designs integrate with your existing equipment. Available with integrated stainless infeed funnel or removable food-grade plastic funnel.

meTRON™ 05 CR

The meTRON™ 05 CR is a cost-effective metal detector for the examination of bulk material in gravity free-fall applications. This closed collar-style detector monitors liquids, pastes, and slurries conveyed in pipes. It features premium digital controls and offers triple-coil, high-frequency precision. The meTRON™ 05 CR is a one-piece, collar-style metal detector that is designed for implementation in gravity or vacuum/pressure conveying lines.

Special Features:

• Easy installation and operation.

• Equipped with EMFI filters to minimize false signals.

• Standard with 05 controls.

• For non-washdown applications, alternative versions are available.

The meTRON™ CR has high electronics protection rating for durability and safety. Its separate electronics housing simplifies collar placement and daily operation. Beacon and buzzer alarms and product-specific reject mechanisms are available.