We took care to maintain magnetic strength under increased temperatures and incorporated other high-temp features. For example, along with the magnet upgrade, we replaced the standard Lexan viewing window with polycarbonate. Even the plastic knobs are rated for higher temperatures.

The FF350 can be used in any existing plastic molding or extrusion application. Since the housing for the FF350 matches the profile of the standard model, drawers and other accessories can be purchased separately to upgrade FF Drawer Magnets already in use.

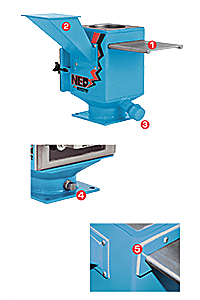

FF350 High-Temp FF Drawer Magnet

- Equipped with high temperature-compensated rare earth magnets.

- Drawer gasket: Viton sponge material rated to 400° F maximum temperature to resist heat aging and compression set.

- Drawer front constructed from Polysulfone material resists temperatures up to 350° F intermittent temperature operation.

- High-torque nylon knobs resist breakage at temperatures up to 350° F.

- Rugged, easy-to-clean 11-gauge stainless steel housing built to support symmetrical 10,000 lb. compression loads.

- Stainless steel center drawer guide simplifies removal and re-installation of the magnet drawer for quick, easy cleaning.

- Superior cartridge geometry and construction increases reach-out and holding power while maximizing cartridge life.

- High-temperature parts are completely interchangeable with the standard FF Drawer Magnet.

Drawer Magnet Options (Available for all FF Drawers):

- No-Spill™ Slide Gate

Patented design allows for complete shut-off of product flow, reducing spillage. - Purge Hopper

Speeds cleaning of your equipment when changing color or compound without sacrificing magnetic protestation. - Dump Tube

Allows operator to completely empty the drawer housing and material hopper of plastic after job is completed. - Liquid Port

Promotes quick addition of color additive into the resin. Port may also be used to hold temperature probe. - Powder Seal Kit

Provides a compression seal around the Slide Gate to prevent leaking of powdery materials.