Used in the Recycling and Aggregate & Mining Industries

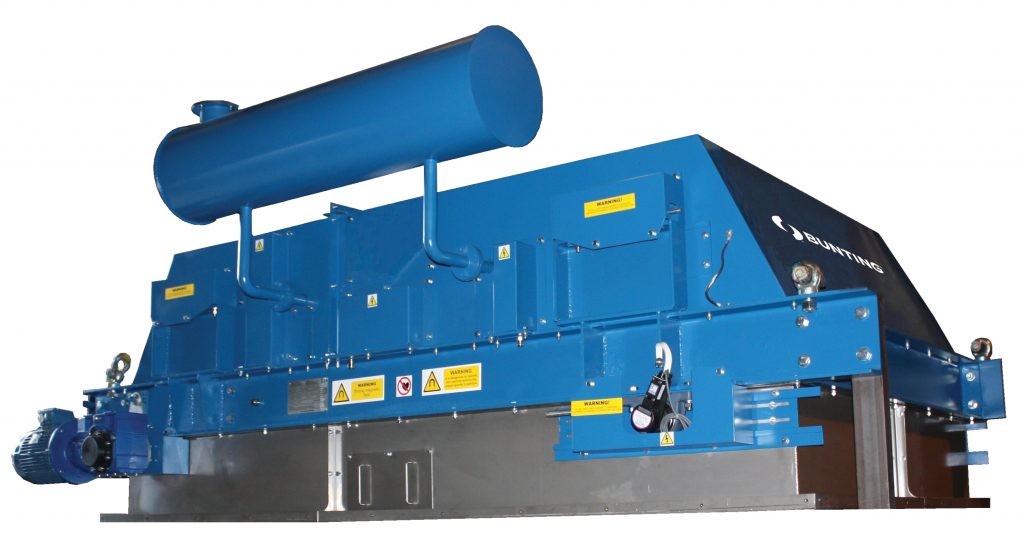

Bunting’s Heavy-Duty Electro Crossbelt Magnetic Separators are the most powerful crossbelt separators available from our current range of products. A wide range of sizes are available for this type of separator, ensuring you will be able to find an option that meets your needs. This separator possesses extremely high magnetic strength, and can work at the increased operating gap necessary to extract ferrous material from deep troughed conveyors.

Most commonly, these electro crossbelt magnetic separators are utilized by the aggregate, mining, mineral, and recycling industries. They are typically positioned across conveyor belts or inline over the head pulleys. These separators are available in standard models suitable for operation over 24 to 78 ½” conveyor belts. Additionally, Bunting offers extensive custom design options to suit larger conveyor belt widths. Additional support structures are also available.

Air or Oil Cooled Systems Available

Oil cooled systems efficiently maintain an optimum working temperature and are capable of producing a slightly higher magnetic force than equivalent air cooled models.

The air-cooled option is used in applications where a customer does not wish to use oil, often based on health and safety considerations such as reducing the risk of a fire hazard. Air cooled heavy-duty crossbelts also have lower maintenance requirements.

Benefits of Bunting Heavy-Duty Magnetic Crossbelt Separators:

- Overall low operating costs keep your facility moving and your budget in check.

- Self-cleaning mechanism minimizes downtime and greatly improves operational efficiency.

- Designed to be virtually maintenance free, reducing costs, downtime, and stress.

- Advanced safety features protect your employees as well as the equipment in your facility.

- Versatile mounting options facilitate ease of installation.