Eddy Current Separators

Bunting’s Eddy Current Separators are used in a wide range of industries, including plastics, recycling, auto shredding, and more. By using cutting edge Magnetic Finite Element Design, the equipment’s magnetic field is optimized, maximizing performance and leading to the highest standard of metal removal.

Our Eddy Current Separators use a magnetic field not to attract ferrous metals, but to repel non-ferrous metals away from the magnetic field and into a collection area. This method allows for the separation of non-ferrous metals such as aluminum, copper, and brass. By implementing Eddy Current Separators in your facility, you will have no problem achieving your separation goals. Whether you are seeking higher levels of recovered metal or improved product purity, our Eddy Current Separators are a highly effective solution.

Request Quote

High Frequency Eddy Current Separator

Optimized magnetic field. Maximum gauss intensity. Intense separation power. The High Frequency Eddy Current Separator has been designed both magnetically and structurally to produce some of the highest throwing and separation forces in the industry. It is ideal for separating…

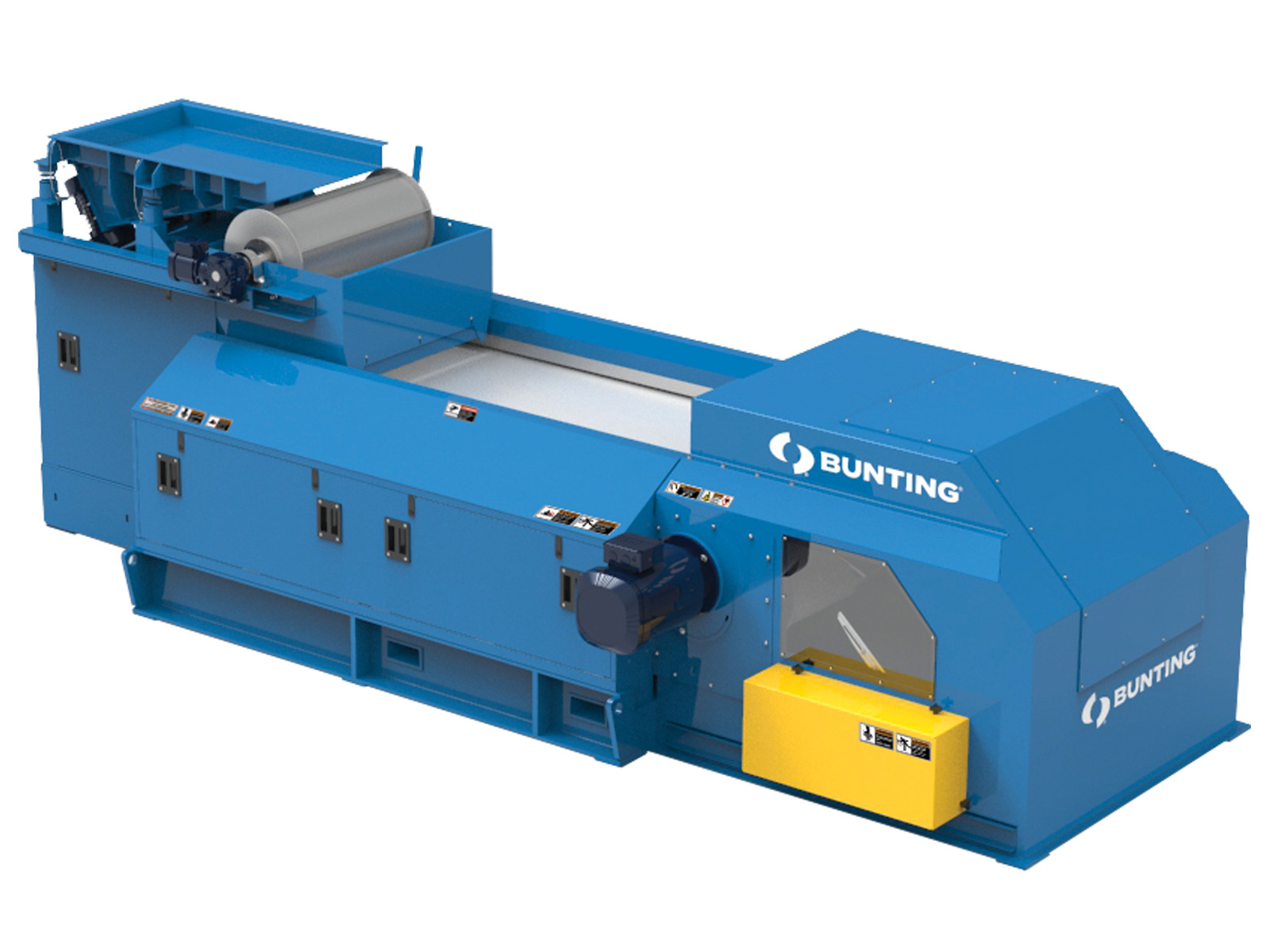

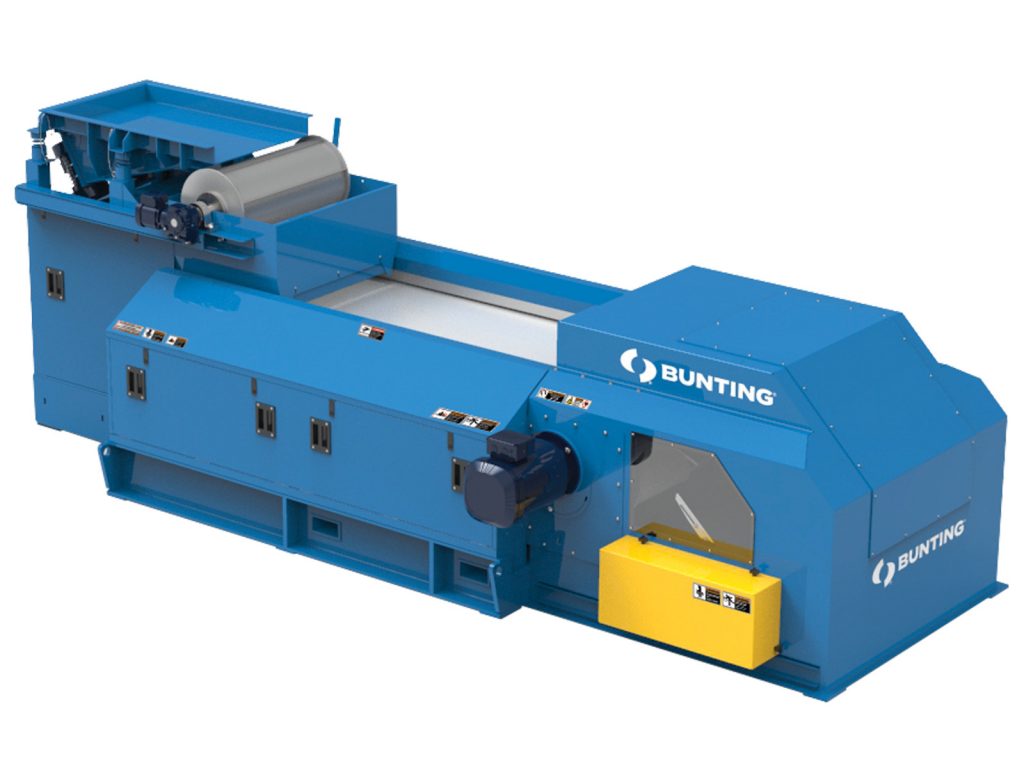

Standard Eddy Current Separator

Flake Eddy Current Separator (ECS) Designed to provide the highest eddy current fields Low maintenance conveyor with an extremely tough urethane belts for longer wear. Cantilever frame weldment design allows easy slip off and on belt change within minutes. Double…

Heavy Duty Eddy Current Separator

Eddy Current Separator Operating Principles The Eddy current separator starts with a short belt conveyor with a high speed magnetic rotor system installed at the discharge end and its drive located at the return end. The magnetic rotor is positioned…