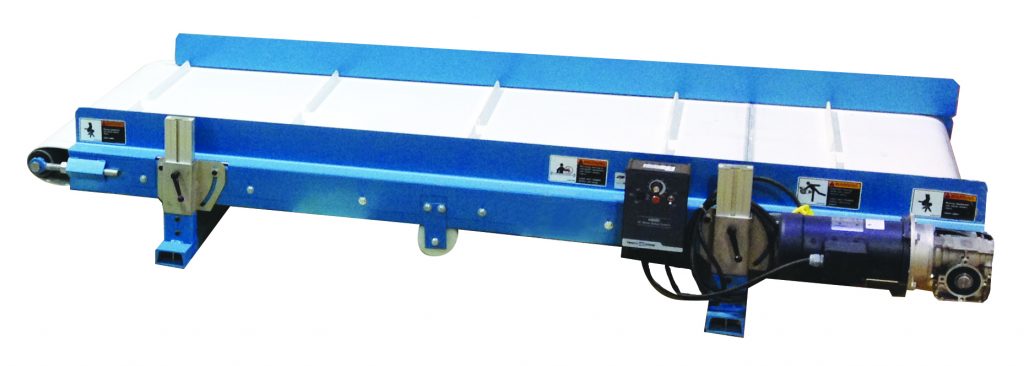

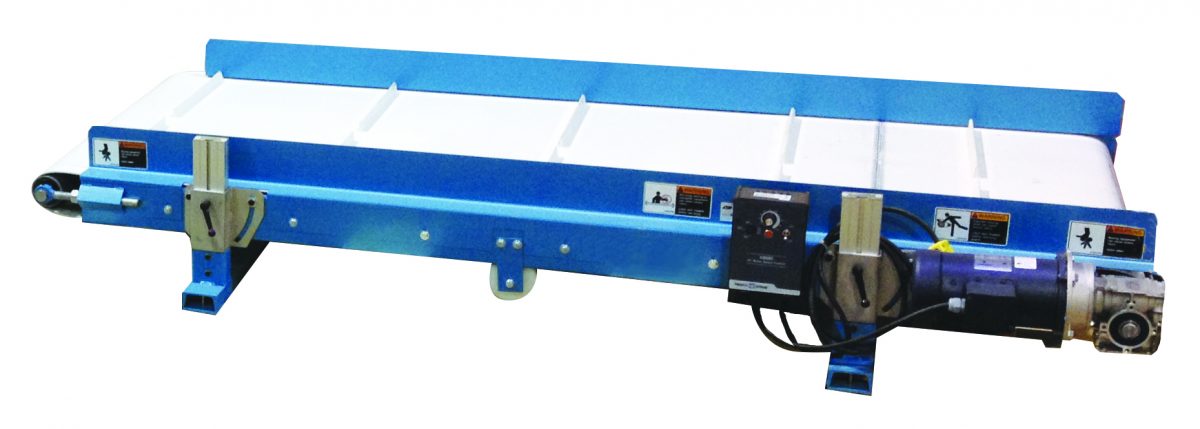

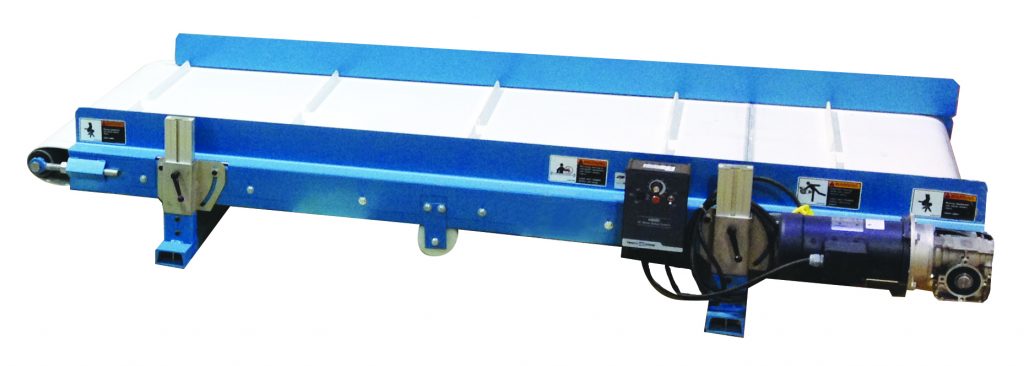

Move-IT™ Part Transfer Conveyors

Conveyor Specs

- Sturdy formed steel frame construction, heavy-duty bearings and simple straight-forward design that is both reliable and easy to maintain.

- Electrical components and variable-speed drive motors are available to match the power needs of each installation.

- Durable cleated belts allow you to move parts and scrap up and down inclines as well as along horizontal runs for maximum layout flexibility.

- Belt styles include: standard fabric or mattop belts, cleated belts for steep inclines, or scoop cleated belting for maximum versatility.

- Several styles to choose from

Part Conveyor Styles

Style A-Frame Conveyor

Suited for horizontal or incline conveying. • Great under-press applications, box transfer, and scrap removal.

- Optional built-in chute collects parts or scraps for transport.

- Standard belts can be used for 10° inclines. For higher angles, cleated belts keep materials moving.

Style B – Gooseneck

- Designed to receive parts that discharge underneath machinery and convey them where needed.

- Standard belts are PVC with 1 1/2″ cleats and polypropylene belts with 2-inch cleats, both on 16 inch centers.

- Standard in-feed flaps contains product.

Style C – Z-Shape

- Design combines the capabilities of horizontal and incline conveyors in a single unit.

- Able to collect parts from underneath machinery.

- The standard fabric belt is PVC with 1 1/2″high cleats on 16 inch centers.

- Incline angles are 30°, 45°, and 60°.

- In-feed flaps to contain products are standard.

Style D – Noseover

- Made to receive parts from overhead and transfer them to a lower level, but can also be used to elevate parts where needed.

- Available with high friction or cleated belts, depending on the part and the incline.

- Incline angles are 30°, 45°, and 60°.

Style E – Elevator

- Designed to receive small parts from overhead operations and convey them down to consolidation areas.

- Offer inclines of 45°, 60°, and 75°.

- Standard fabric belt is PVC with 1″ cleats on 6″ centers. Higher cleats are recommended for steep inclines.

- In-feed hoppers and discharge chutes are standard equipment.