Protect Your Product & Equipment with Metal Detectors for Conveyors

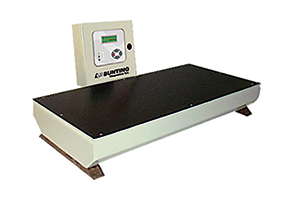

meTRON™ 03 SL

- Minimal conveyor modification required to install

- Balanced-coil technology for more accurate detection

- Integrated Metal Free Zone

Installed directly under conveyor belts, triple-coil MeTron™ SL Detectors monitor flat products and materials with shallow burden depths.

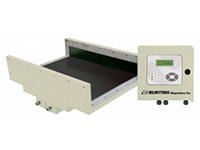

meTRON™ 05 S

- Features Triple-coil circuitry for accuracy

- Equipped with EMFI filters for reduced waste, misses, and false alarms

- Features low-profile construction and superior reach-out

- Reject options include pusher, flap, and cut-out devices

- Uses 05 Controls

These single-sided, triple-coil under-the-belt detectors install in belt conveyor systems and scan through the belt into product with a maximum burden depth of six inches. This single surface detector works well for Belt Conveyors and Vibratory Chutes.

meTRON™ 05 VT

- User-friendly installation

- No metal-free zone

- Easy operation

Designed to fit into vibration conveyors with little modification. Models are available to fit a wide range of shapes and sizes.

An integrated vibratory conveyor can be purchased with the detector. Options include warning devices, conveyor reverse, and reject event counter.

meTRON™ 05 D

- Waterproof construction

- Automatic product tracing

- Temperature compensation

- Built-in digital event counter

- Epoxy-filled search head (extremely solid)

- Serial Interface (RS-232)

- Multi-level password protection

- Select pusher, flap, or cut-out rejection devices

- Signals include beacon, buzzer, and beacon plus siren warnings.

- Combination assemblies with detector & conveyor can be custom built to your application

The MeTron™ D is a two-piece tunnel-style detector that separates to install around belt conveyors and pneumatic lines. It offers triple-coil sensitivity and accuracy. It is easy to install and provides stable performance. This two-piece tunnel-style detector is perfect for Belt Conveyors and Vibratory Chutes.