About Conveyor Detectors for Non-Wovens

The most common type of foreign material in the Non-Woven Industry are broken needles and other types of metal. Successful detection and separation of this metal will protect your customer, brand, and reputation. This helps build loyalty and profitability. Our equipment senses and removes ferrous, non-ferrous and stainless metals in any fluff, fleece or material, even metallic bits in moist products such as wipes.

profiLINE Metal Detection Bar

- Flat coil detector available in two styles

- Model 04: Multi-segment metal detector (300mm spacing)

- Model 05: Single-segment metal detector

- Detects broken needles and other loose metals including damp product

- Detects metals in fabrics with pinpoint accuracy.

- Available up to 12 meters wide (40 feet)

- Easily installed horizontally or vertically because it is secured at two points

- Manufactured for maximum life even in the roughest environments

- Extremely low profile

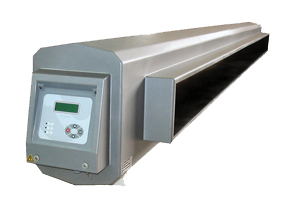

powerLINE 05 Detector

- Metal Separator for suction and pressure lines, ideal for purifying fluff and fillers.

- Fast installation with quick-connect clamps

- Fully sealed sensor head to eliminate false rejects from electronic interference.

- Minimize loss of good material by up to 90%

- Perfect fit for fiber inspection

- Positive speed control monitors contaminant speed to set the precise reject time and duration to cut good product loss

- Eject gate available

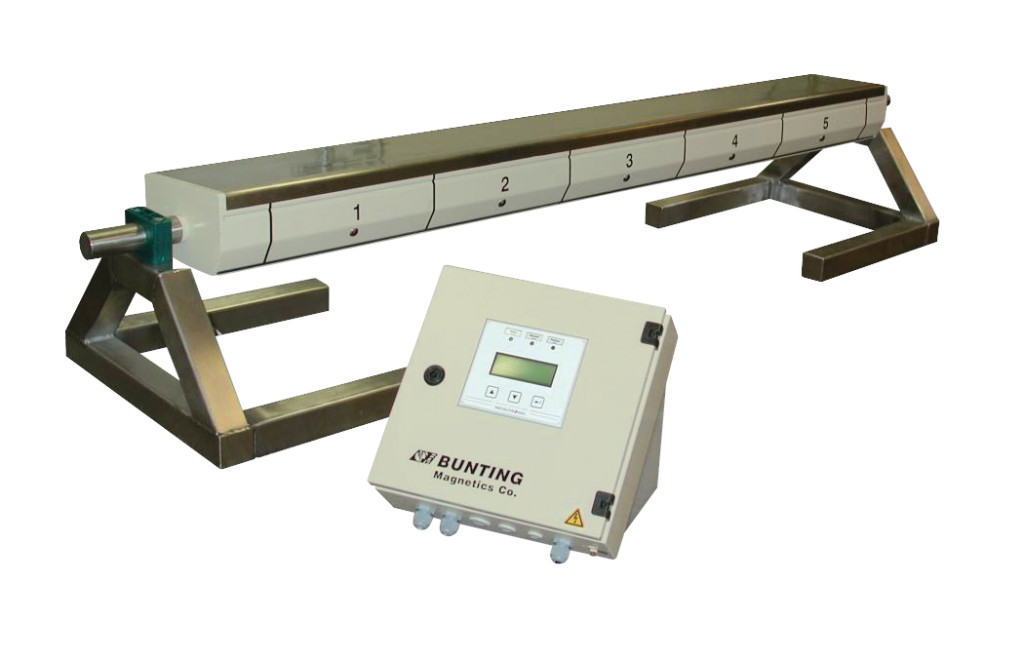

meTRON 05 Detector

- Tunnel-style detector to effectively examine conveyed fabrics and materials.

- For product thicker than 20cm (approx. 8 inches)

- High sensitivity in industrial environments

- Automatic product tracing

- Multi-level password protection

- Built-in digital event counter

- Available in various sizes (integrated controls on larger units)

- Installs horizontally or vertically in minimal space