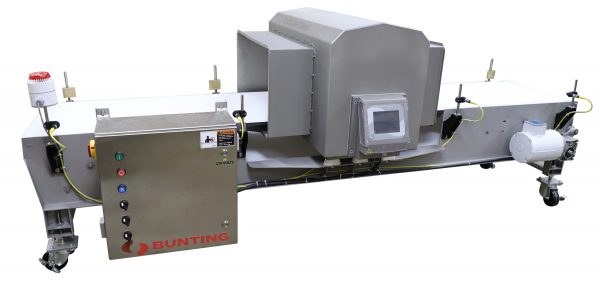

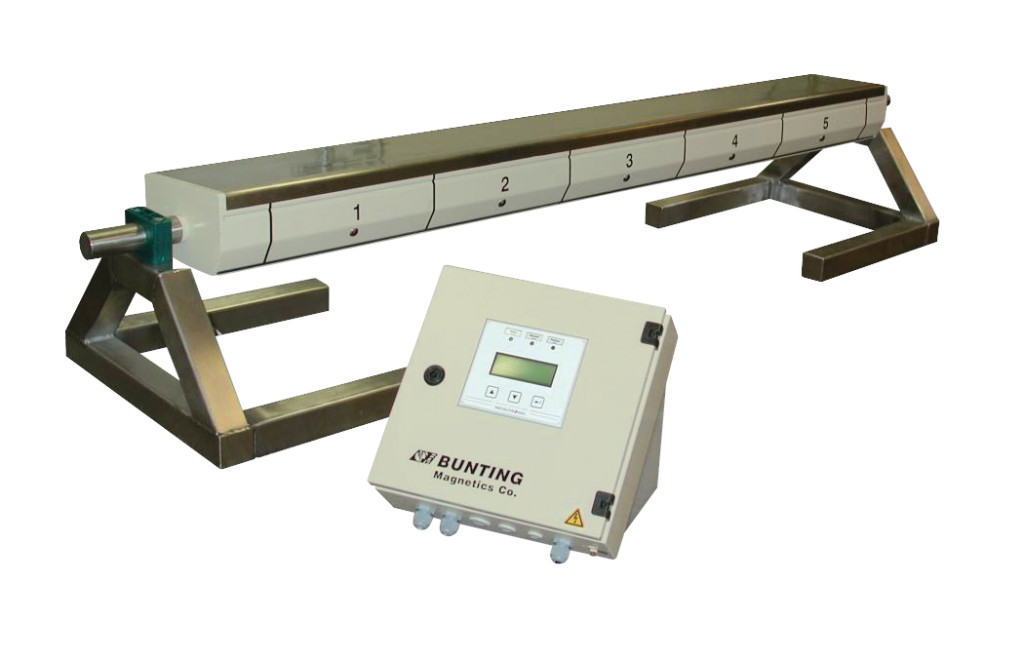

Metal Detection for the food, plastics, recycling, manufacturing, and other processing industries.

Features of all Bunting® Metal Detection Equipment

Innovative triple coil design

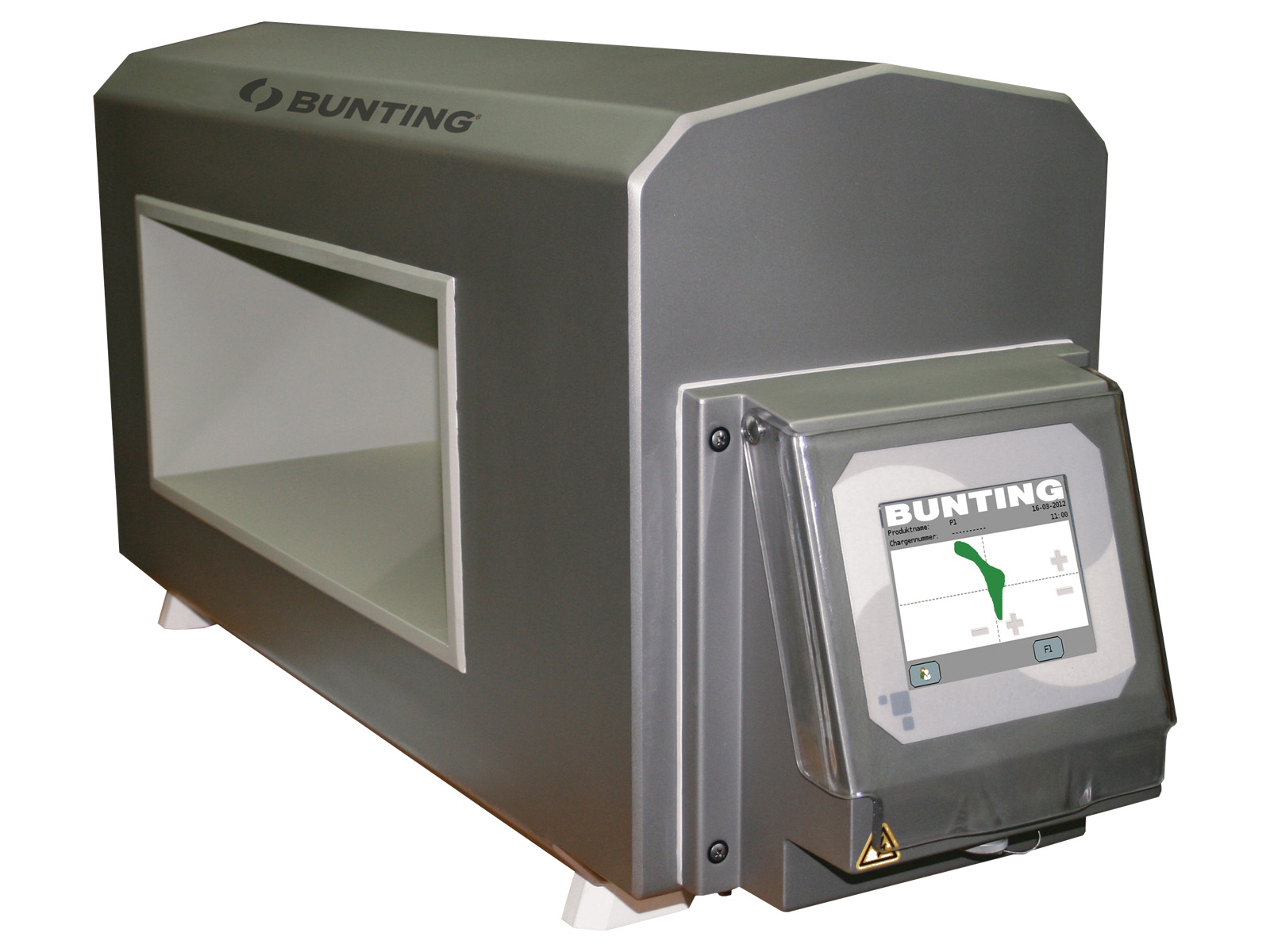

Bunting® Metal Detectors utilize triple coil design for the search head. This is comprised of windings around an aperture opening, whether round, or rectangular. There is a transmitter in the center, and two receivers (one at entrance of the search head, and one at the exit). Within the aperture opening, an electromagnetic field is created. When a piece of metal passes through the coil opening, a signal is generated and calculated at each and activates further operations or devices.

Resistant to water, vibration, and other interference

Metal detectors are highly sensitive pieces of equipment, and need to be protected from environmental interferences such as vibration and other electrical fields.

All search heads are filled with a catalyzed epoxy. There are no empty voids inside the housing, thereby eliminating the possibility of water intrusion to the coil, making them easy to clean. This exclusive epoxy also reduces the effect of vibration to the search head. Coils and electronics can be rated from IP54, to IP66 and IP69K.

Additionally the search head is manufactured with a special shielding against outside interferences. This allows Bunting® Metal Detectors to perform better in difficult environments, and require shorter metal free zones than our competition.

Software for enhanced quality control

Depending on the level of electronics you select, Bunting® Metal Detectors have recording and reporting functions within the software. Optional features allow your organization to network detectors for remote monitoring, reporting or control.