Safeguard Your Product Quality and Protect Your Equipment

Sanitary-Grade Metal Separation Equipment

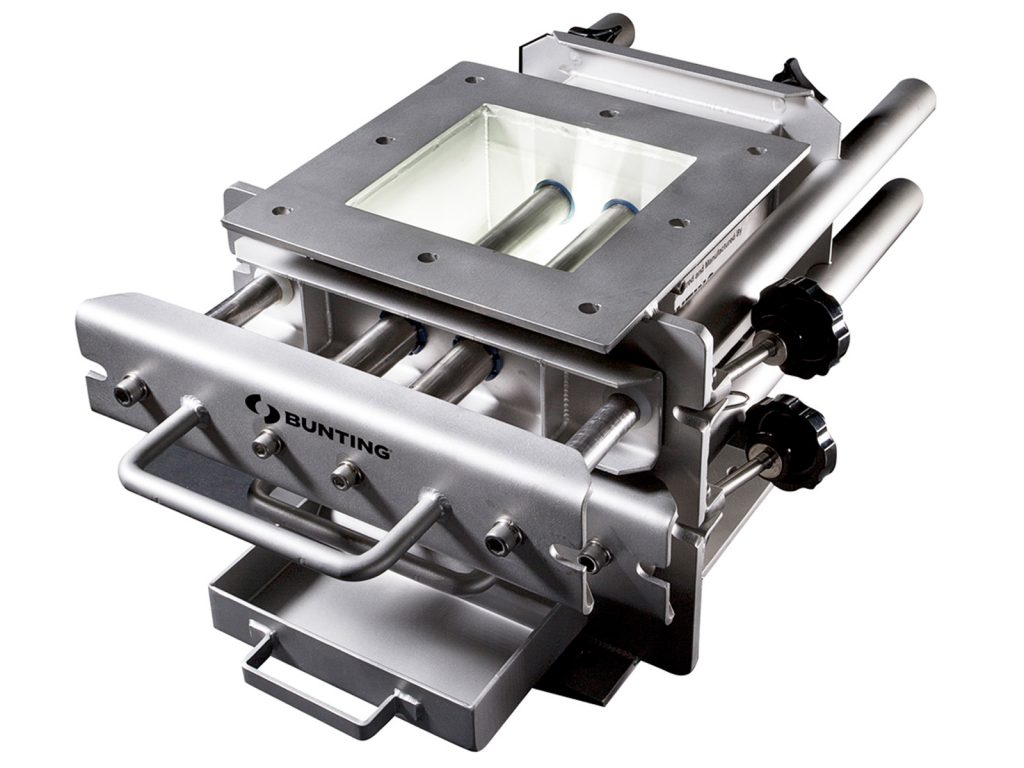

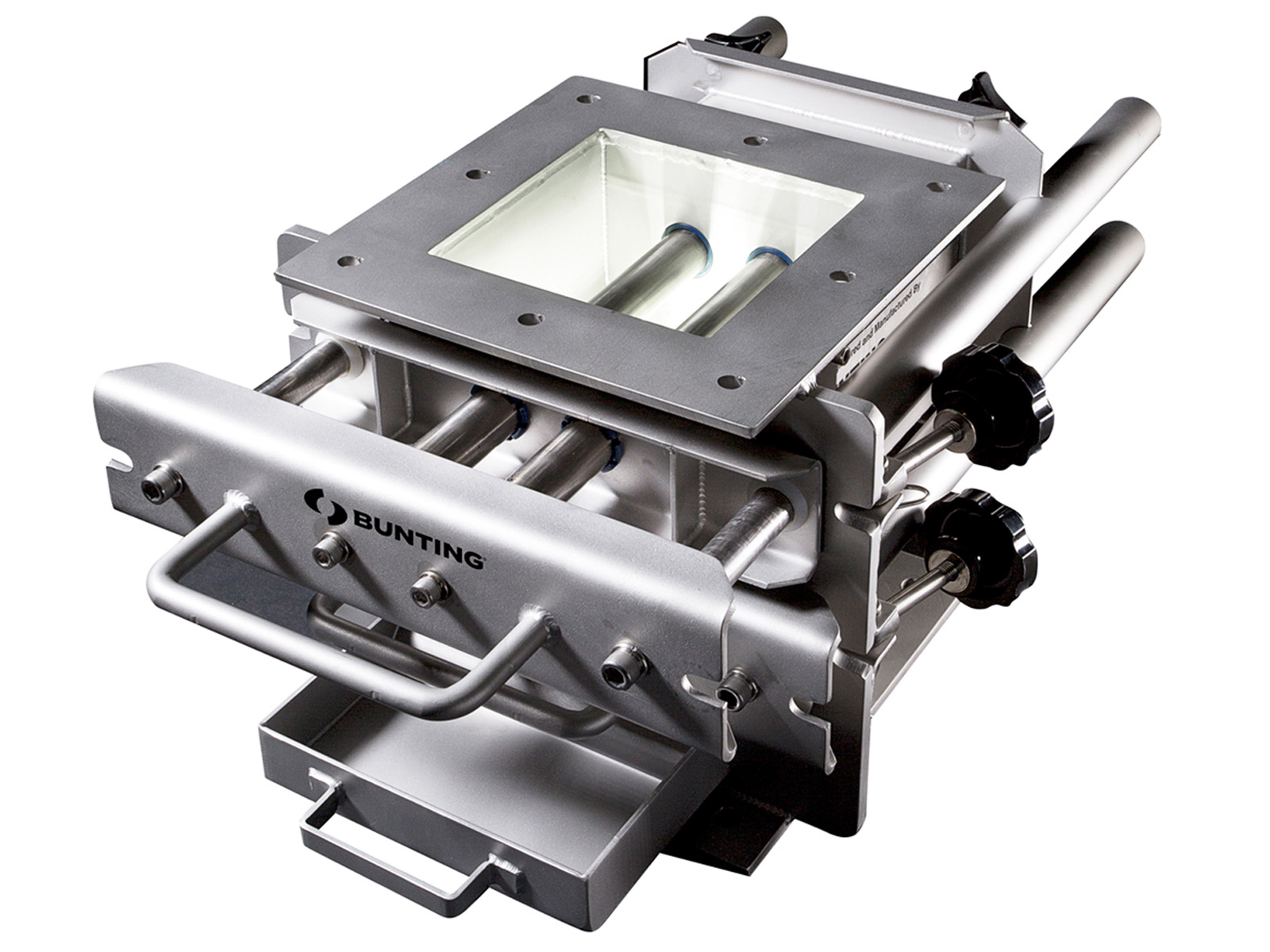

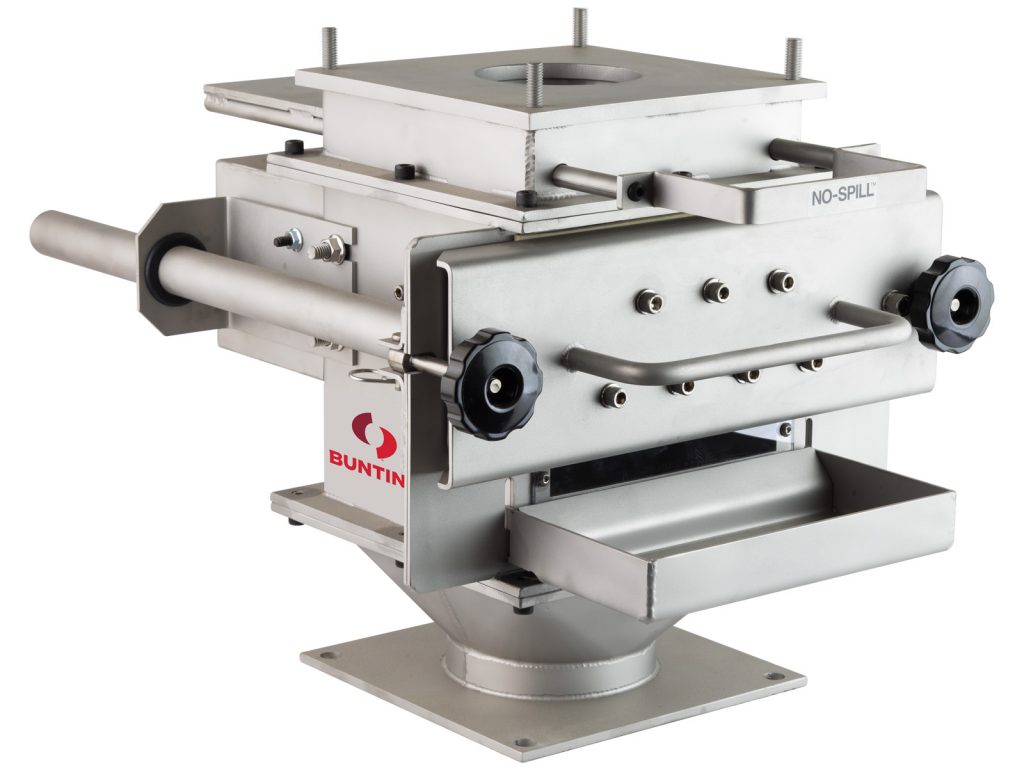

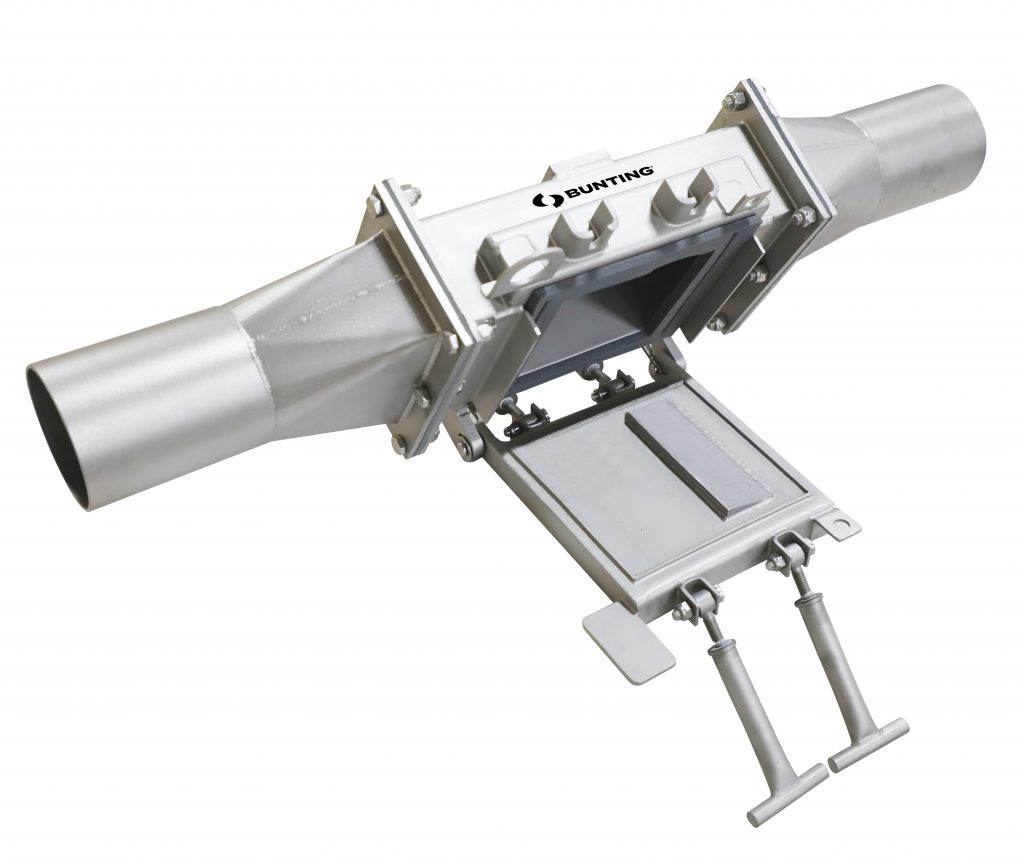

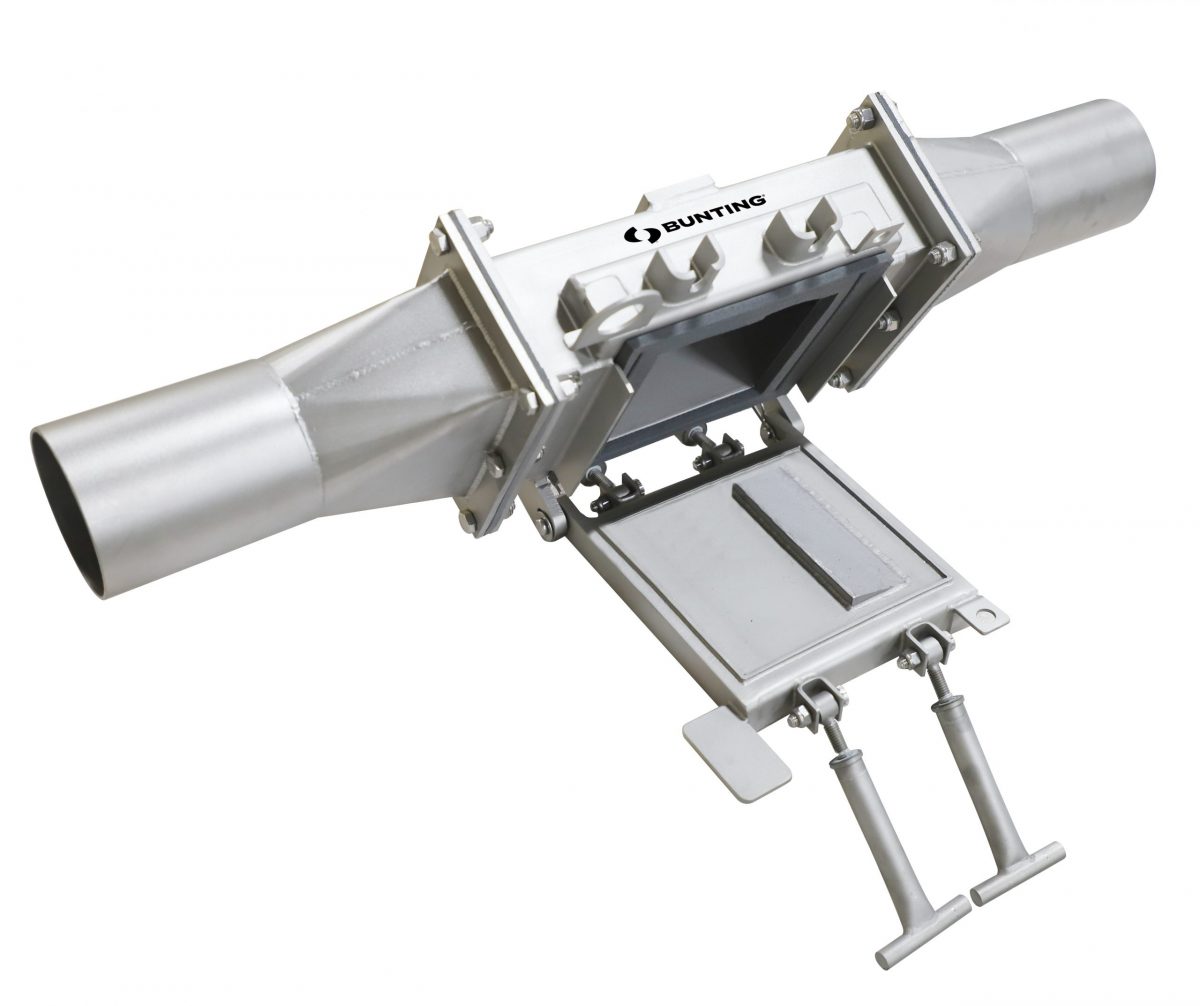

Our sanitary-grade metal separators are the first separators to earn USDA, AMS-Acceptance. Our engineers refined existing designs to help processors meet increased marketplace demands and governmental requirements for safer and purer foodstuffs, meats, pharmaceuticals, and chemicals. All of these approved models have met or exceeded the USDA, AMS criteria as published in the NSF/ANSI/3-A 14159-1 2002 specifications, passed inspection, and earned the right to bear the USDA, AMS Meat and Poultry Accepted Equipment logo.

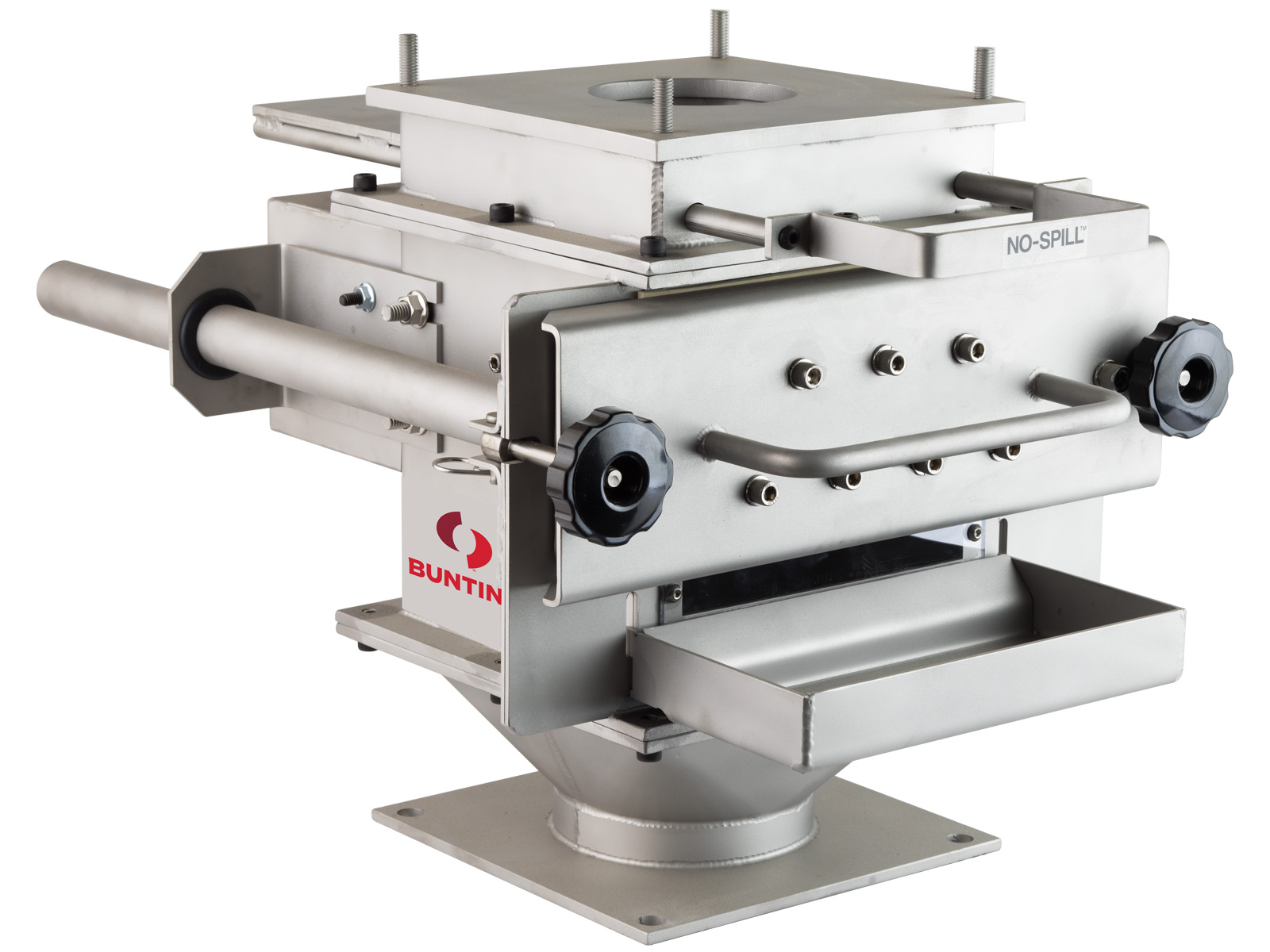

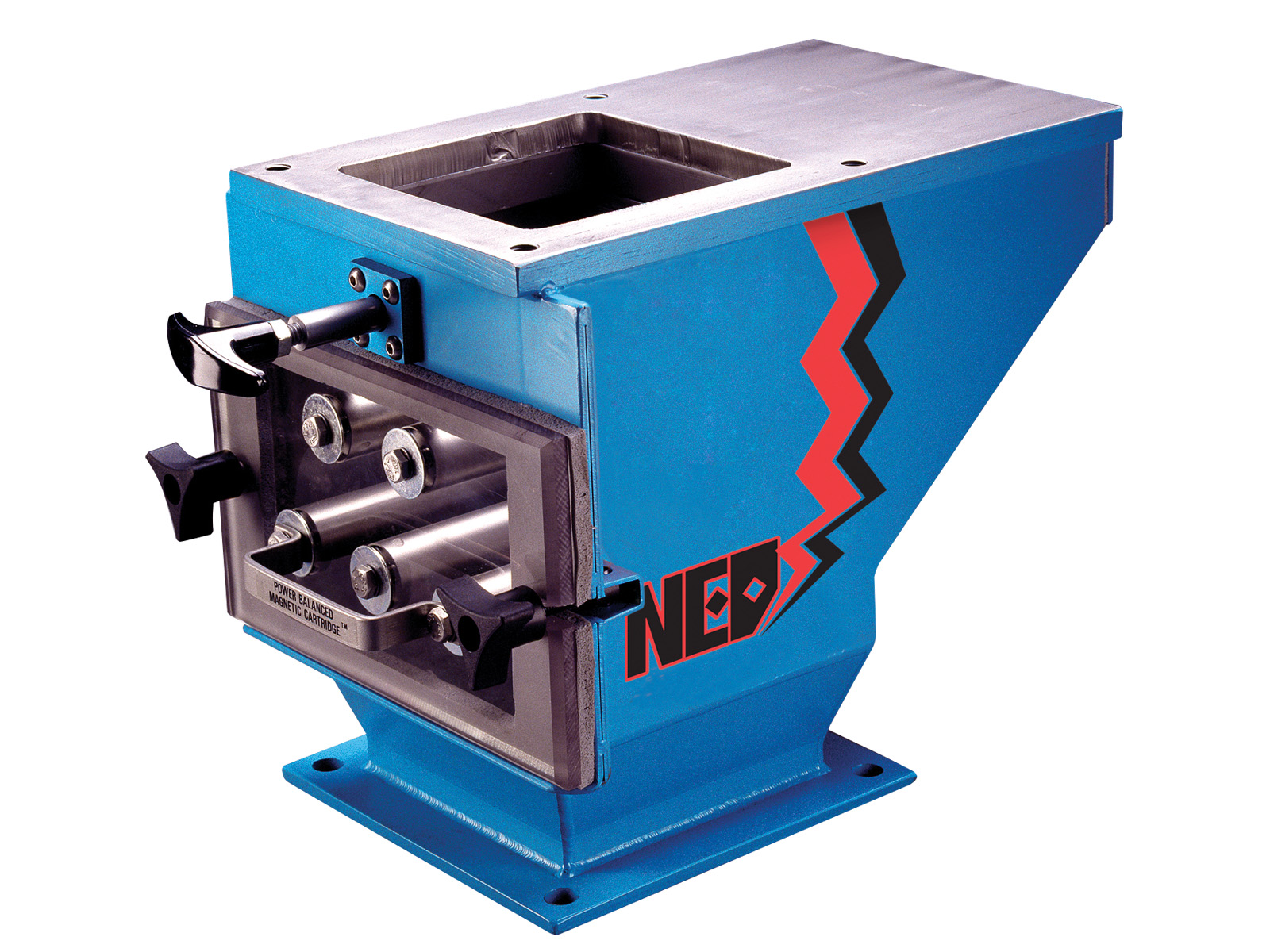

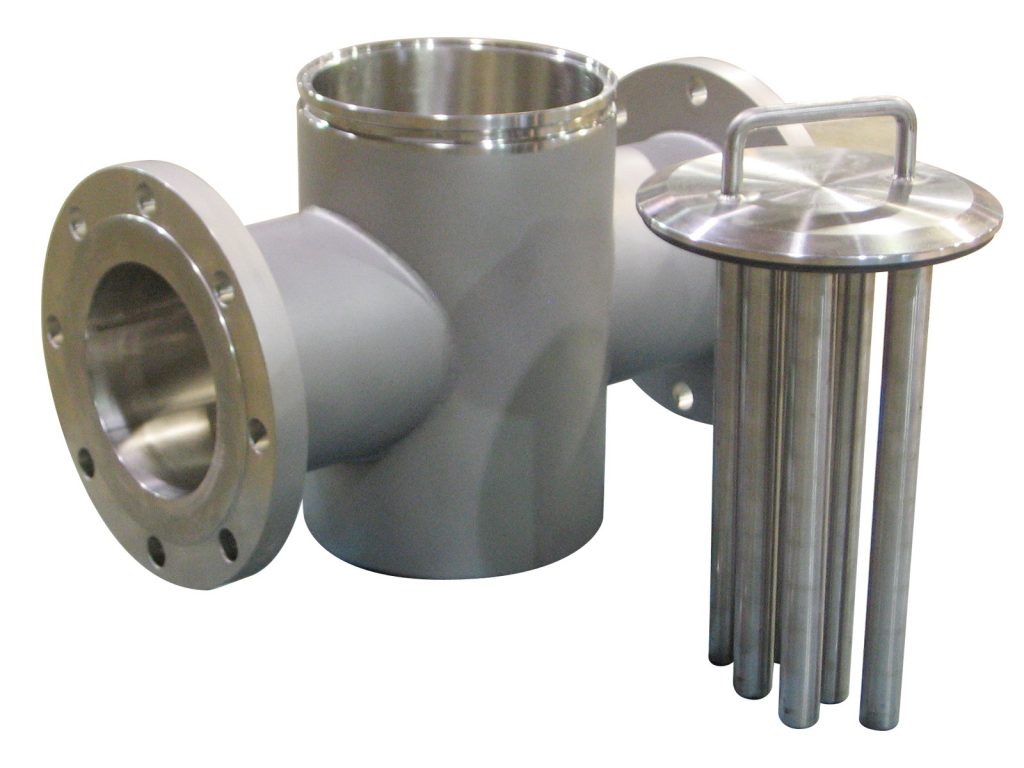

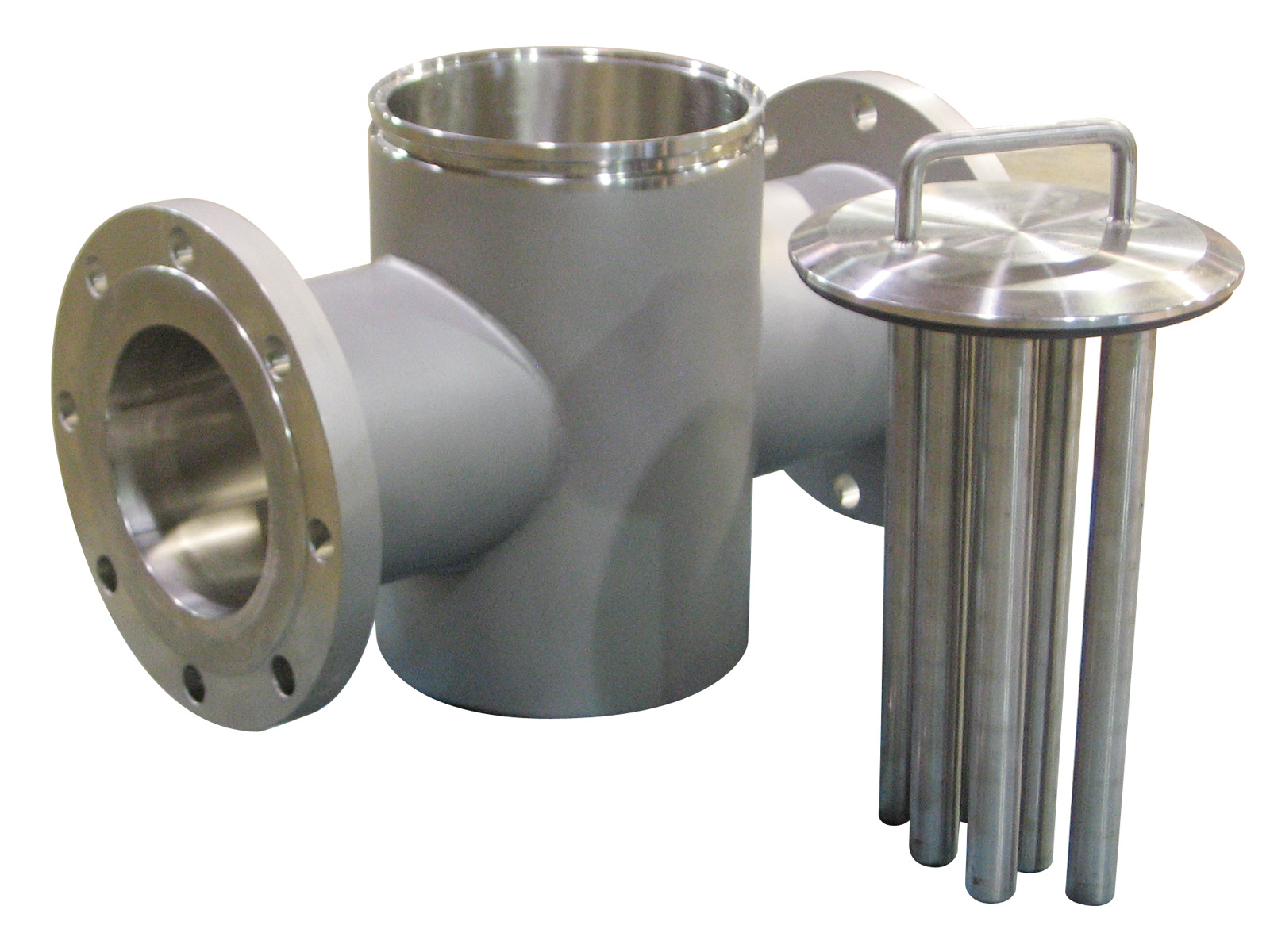

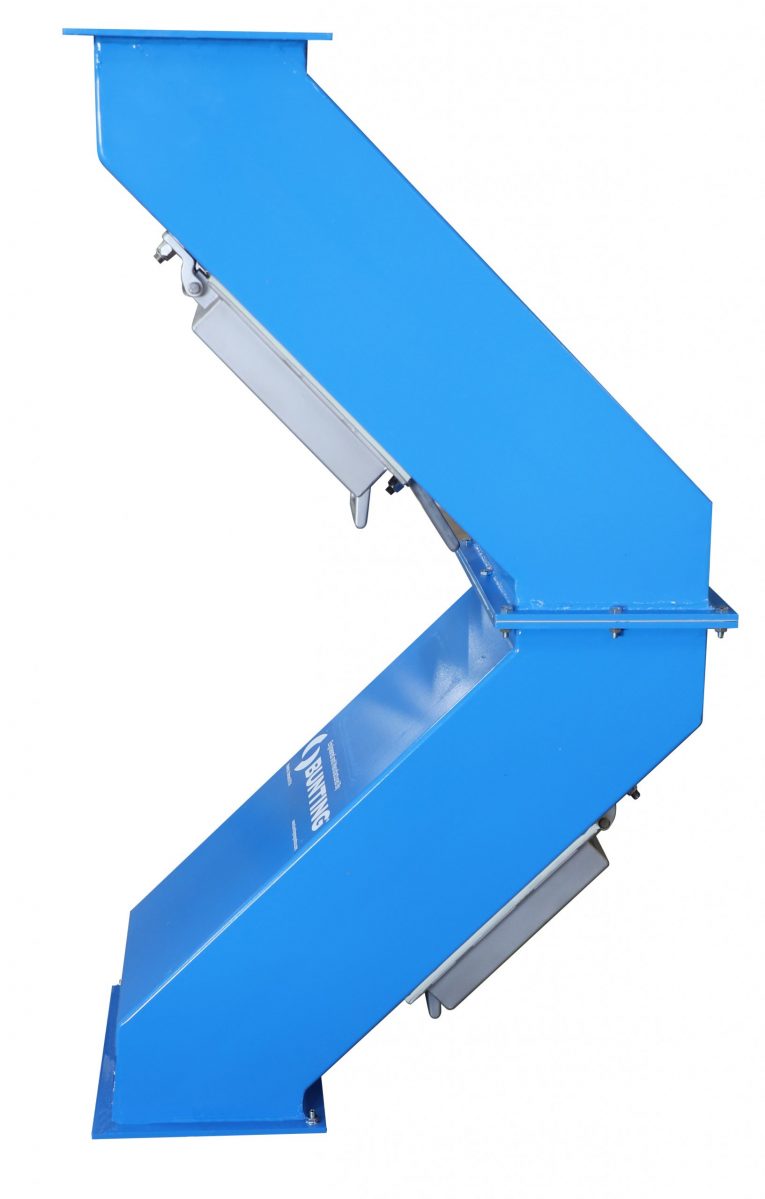

Trap, Drawer, In-line, Hump and Wedge Magnets—we manufacture those, and more, for your separation applications.

Metal-Detectable Gaskets and Grommets add another layer of safety in our food-grade (or higher) Magnetic Separation equipment including HF Drawer Filters, Magnetic Liquid Traps, In-Line Magnets, Hump Magnets. Your increased demands for product safety are met even more with this industry-leading feature. With Metal-Detectable Gaskets and Grommets, if a piece chips off or the gasket breaks, it is immediately caught by the equipment’s magnetic cartridge or plate. The broken piece can also be seen in any metal detection or x-ray system.